Oomatshini bokuwelda beLaseryindlela yokuwelda esebenzayo nechanekileyo esebenzisa umqadi welaser woxinaniso olukhulu njengomthombo wobushushu.Ukuwelda kweLaser yenye yezinto ezibalulekileyo ekusetyenzisweni kobuchwepheshe bokusetyenzwa kwe-laser.Ngeminyaka yee-1970, yayisetyenziselwa ukuwelda izixhobo ezinodonga olucekethekileyo kunye nesantya esisezantsi sokuwelda.Inkqubo ye-welding yohlobo lwe-thermal conduction, oko kukuthi, umphezulu we-workpiece ufudunyezwa yi-radiation ye-laser, kwaye ubushushu bomhlaba busasazeka ngaphakathi ngokuqhuba kwe-thermal.Ngokulawula ububanzi, amandla, amandla encopho kunye nokuphindaphinda ukuphindaphinda kwe-laser pulse kunye nezinye iiparameters ukunyibilikisa i-workpiece kunye nokwenza i-pool ethile etyhidiweyo.Ngenxa yeenzuzo zayo ezizodwa, isetyenziswe ngempumelelo kwi-welding echanekileyo ye-micro and small parts.

一、 Iimpawu zokuwelda

Yeyokudityaniswa kwe-welding, esebenzisa i-laser beam njengomthombo wamandla ukuba nefuthe kwi-joint weldment.

Umqa we-laser unokukhokelwa yinto ekhanyayo, enjengesipili, kwaye emva koko iqikelelwe kumthungo we-weld ngento ebonakalisayo okanye isipili.

I-laser welding is non-contact welding, akukho xinzelelo olufunekayo ngexesha lokusebenza, kodwa igesi ye-inert iyadingeka ukukhusela i-oxidation ye-pool etyhidiweyo, kunye nentsimbi yokuzalisa isetyenziswa ngamaxesha athile.

I-laser welding inokudibaniswa ne-MIG welding ukwenza i-laser MIG composite welding ukuphumeza i-welding enkulu yokungena, kwaye igalelo lobushushu liyancipha kakhulu xa kuthelekiswa ne-MIG welding.

二、Umgaqo osebenzayo womatshini wokuwelda

Umatshini we-laser welding we-mold nawo lisebe leumatshini welding laser, ngoko ke umgaqo osebenzayo kukusebenzisa i-laser pulses ephezulu yamandla ukutshisa indawo kwindawo encinci.Amandla emitha yelaser asasazeka kwizinto ngokuqhuba ubushushu, kwaye izinto ziyanyibilika zenziwe.ichibi elithile elinyibilikayo.Luhlobo olutsha lwendlela yokuwelda, ubukhulu becala ukuwelda kwezixhobo ezibhityileyo kunye neenxalenye ezichanekileyo, kwaye inokuqonda ukuwelda, i-butt welding, i-stitch welding, i-welding yokutywina, njl njl. umthungo, akukho mfuneko okanye unyango olulula emva kwe-welding, umgangatho ophezulu we-welding seam, akukho pores, ulawulo oluchanekileyo, indawo encinci yokugxila, ukuchaneka kokubeka okuphezulu, kunye nokuzenzekelayo okulula.Oomatshini bokuwelda belaser bamandla aphezulu baqalisiwe, kwaye izitayile ezahlukeneyo zoomatshini bokuwelda kwelaser kunye nokulungiswa kunokuqondwa kwizinto ezityebileyo.

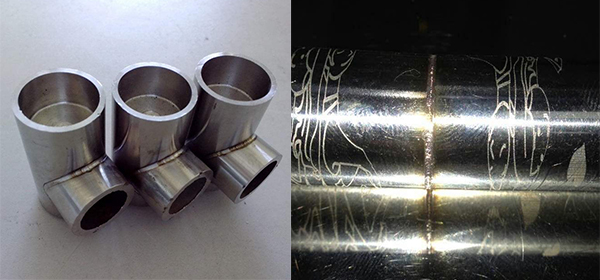

Isampulu:

三、 Iimpawu zokuwelda i-laser mold

Umatshini we-laser welding welding wamkela umboniso omkhulu we-LCD we-Chinese interface, okwenza kube lula kumqhubi ukuba afunde kwaye asebenze.Isixhobo kwakhona samkela umsebenzi wenkqubo yefonti ukuqonda umsebenzi weendlela ezininzi, ezilungele ukulungiswa kokungunda kwezinto ezininzi.Akukhona nje indawo echaphazelekayo yokushisa incinci, izinga le-oxidation liphantsi, kodwa kwakhona akuyi kuba ne-blisters, iipores kunye nezinye izinto.Emva kokuba i-mold ilungiswe, umphumo wokulungiswa kukufezekisa ukungalingani kwi-joint, kwaye ayiyi kubangela ukuguqulwa kwesikhunta.

四、Uqwalaselo kunye neteknoloji yokusetyenzwa

1.Umngundoumatshini welding laserkufuneka asebenzise imakroskopu eyi-10X okanye eyi-15X ukujonga ukusebenza.

2. Unikezelo lwamandla kumatshini we-laser welding we-mold unokwamkela umsebenzi ohlengahlengiswayo we-waveform, olungele ukuwelda kwezinto ezahlukeneyo.Okunje: intsimbi yokufa, insimbi engenasici, i-beryllium yobhedu, i-aluminiyam, njl.

3. Inkqubo yeCCD (inkqubo yekhamera) ingasetyenziselwa ukubeka iliso, umsebenzi ngulo: ukongeza kumqhubi ojonga kwi-microscope, abangasebenzisiyo banokubukela yonke inkqubo ye-welding ngokusebenzisa isikrini sokubonisa inkqubo yekhamera, esi sixhobo kunenzuzo ekungaphangeliyo Uqeqesho lobugcisa lwabasebenzi kunye nemiboniso yemiboniso idlale indima entle ekukhuthazeni iteknoloji ye-laser welding.

4. Iyakwazi ukunyibilika iingcingo ze-welding zobubanzi obuhlukeneyo, ukusuka kwi-0.2 ukuya kwi-0.8 ububanzi.

5. Umatshini we-laser welding welding kufuneka ukhuselwe ngegesi ye-argon, kwaye inkqubo kufuneka imiselwe ukukhupha igesi ye-argon kuqala kwaye emva koko i-laser ukuthintela i-oxidation ye-laser yokuqala ye-pulsed ngexesha lokucubungula okuqhubekayo.

6. Xa i-mold i-laser welded, eyona nto ixhaphakileyo kukuba kukho amanqaku okuluma malunga nenxalenye ye-welding.Kuyimfuneko ukusebenzisa indlela ye-laser yokubetha umoya ukugubungela utshintsho olunokubangela iimpawu zokuluma ukuthintela ukwenzeka kwamanqaku okuluma.Kwanele ukuba indawo yokukhanya idlula umda we-welding position nge-0.1mm.

Ixesha lokuposa: Jun-12-2023