Umatshini wokumakisha weLaserkukusetyenziswa kwemiqadi yelaser ukuphawula ngokusisigxina umphezulu wezinto ezahlukeneyo.Isiphumo sokumakisha kukuveza imathiriyeli enzulu ngokuba ngumphunga wezinto ezingaphezulu, okanye “ukukrola” umkhondo ngeekhemikhali kunye notshintsho lwenyama yemathiriyeli engaphezulu ebangelwa ngamandla okukhanya, okanye ukutshisa inxalenye yento ngokusebenzisa amandla okukhanya. , ebonisa i-etching efunekayo.ipateni, isicatshulwa

Usetyenziso:

Uyakwazi ukukrola iintlobo ngeentlobo zemathiriyeli engeyiyo eyentsimbi.Isetyenziswa kwiimpahla zempahla, ukupakishwa kwamayeza, ukupakishwa kwewayini, iiseramikhi zokwakha, ukupakishwa kwesiselo, ukusika ilaphu, iimveliso zerabha, iipleyiti zamagama eqokobhe, izipho zobugcisa, izinto ze-elektroniki, isikhumba kunye namanye amashishini.

1. Iyakwazi ukukrola isinyithi kunye nezinto ezahlukeneyo ezingezizo ezentsimbi.Ifaneleke ngakumbi ukulungiswa kweemveliso ezithile ezifuna ukuchaneka okulungileyo kunye nokuchaneka okuphezulu.

2. Isetyenziswe kumacandelo e-elektroniki, iisekethe ezidibeneyo (IC), izixhobo zombane, unxibelelwano lweselula, iimveliso ze-hardware, izixhobo zesixhobo, izixhobo ezichanekileyo, iiglasi kunye neewotshi, ubucwebe, iinxalenye zemoto, amaqhosha eplastiki, izinto zokwakha, iipayipi zePVC, izixhobo zonyango kunye nezinye. amashishini .

3. Izinto ezisetyenziswayo ziquka: isinyithi esiqhelekileyo kunye ne-alloys (zonke isinyithi ezifana nentsimbi, ubhedu, i-aluminium, i-magnesium, i-zinc, njl.), isinyithi esinqabileyo kunye ne-alloys (igolide, isilivere, i-titanium), ii-oxide zetsimbi (zonke iintlobo ze-oxides zetsimbi zifana ne-alloys). eyamkelekileyo), unyango olukhethekileyo (phosphating, aluminiyam anodizing, electroplating surface), izinto ze-ABS (igobolondo lesixhobo sombane, iimfuno zemihla ngemihla), inki (izitshixo eziguquguqukayo, iimveliso eziprintiweyo), i-epoxy resin (i-electronic component packaging, insulating layer).

Umatshini wokuMakisha ubucwebe beLaser:

Iindlela zokumakisha kunye nokukrola umatshini wokumakishwa kwezacholo zefayibha laser zibhetyebhetye kakhulu.Udinga nje ukufaka isicatshulwa esikhankanyiweyo okanye ipateni kwisoftware.Oomatshini bokuphawula beLaser banokuphawula kwaye bakrole iimpawu ezifunwayo ngemizuzwana, banike ubucwebe ubuhle obukhethekileyo bomzobo wesiko.Ukumakishwa kweLaser kwamkela inkqubo yokumakisha engaqhagamshelwanga, esebenzisa i-laser-high-energy-density laser beam ukuze ikhuphe i-irradiate ebusweni bezinto eziphathekayo ukuze ikhuphe imathiriyeli yomphezulu okanye ivelise ukusabela kweekhemikhali ze-discoloration, ngaloo ndlela ishiya amanqaku ahlala njalo.Yonke inkqubo yokukrola ayinakho ukunxibelelana ngokuthe ngqo kunye nobucwebe, akukho friction ngoomatshini, kwaye akukho monakalo kwizacholo.Ukongeza, indawo ye-laser incinci, ukothuka kwe-thermal kuncinci, kwaye iimpawu eziphawulweyo zigqwesile kwaye akukho monakalo kubucwebe.

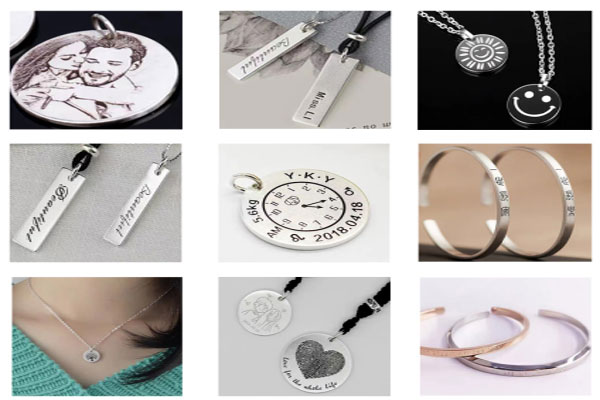

Oomatshini bokumakishwa kwelaser yobucwebe bangoku basetyenziswa ngokubanzi kumacici, iintsimbi zomqala, imisesane, izacholo kunye nezinye iimveliso.Ukhuphiswano kushishino lwezacholo luya lusiba nzima.Iimveliso kwivenkile yobucwebe kwimarike phantse zonke ziyafana.Iindlela zangaphambili zokucutshungulwa ezifana nesitampu sentsimbi, ukukrola kunye nobugcisa bokukrola, indlela yokunyibilikisa, iteknoloji yokufaka emnyama neyesilivere, kunye nentsimbi yeenkozo zomthi zidla ixesha kwaye zibiza kakhulu.Umatshini wokumakisha we-laser jewelry fiber uneempawu zokuchaneka okuphezulu, ofaneleke kakhulu ukukrola oonobumba abangagugiyo kunye nokuqina kumphezulu wezacholo ezixabisekileyo nezincinci ezifana nemisesane kunye nentsimbi yomqala.

Inzuzo:

Iimpawu ezichanekileyo eziphezulu zeoomatshini bokumakisha laserzilungele ukugqiba iisimboli ezingapheliyo zokunxiba kwizinto ezinqabileyo kunye nezacholo ezincinci ezifana namakhonkco kunye neekhola.Kwiindawo ezithengisa ubucwebe zanamhlanje, iimpawu zobuqu zithandwa kakhulu phakathi kwabathengi, njengamagama, iintsikelelo kunye nemifanekiso eyenzelwe wena enentsingiselo ekhethekileyo ephawulwe kubucwebe.Ukongeza, umatshini wokumakisha we-laser unokuzalisa iisimboli ezahlukeneyo kumphezulu wezinto ezininzi ezinje ngobhedu, intsimbi engenasici, isilivere kunye negolide.

1. Umgangatho we-beam ulungile, kwaye unokukrola ngokuchanekileyo ama-workpieces amancinci kakhulu, i-slits i-flat kwaye intle, kwaye isantya sokukrola sikhawuleza, sizisa abathengi amava okusebenza ngokufanelekileyo kunye noqoqosho;

2. Izinga eliphezulu lokuguqulwa kwe-electro-optical, akukho lahleko yokudibanisa amandla, akukho zixhobo, ukugcina iindleko zokusebenza kubathengi.

3. I-laser ye-fiber inobomi obude benkonzo, amandla okuvelisa i-laser ezinzile, ukuthembeka okuphezulu, kunye nokugcinwa ngaphandle kweeyure ze-100,000;

4. Isantya sokumakisha sikhawuleza, ukusebenza kakuhle kuphezulu, ixesha lokucubungula i-batch ye-workpieces lifutshane, kwaye inzuzo ngexesha leyunithi kunye nemveliso enye yandiswa;

I-5.Indiza ekhethekileyo inamandla okwenza ngokwezifiso kwaye inokulungelelaniswa ngokweemfuno zabathengi.

Iindlela zokumakishwa kunye nokukrola umatshini wokumakishwa kwezacholo zefayibha laser

zibhetyebhetye kakhulu.Udinga nje ukufaka isicatshulwa esikhankanyiweyo okanye ipateni kwisoftware.Oomatshini bokumakisha ngeLaserinokuphawula kwaye ikrole iimpawu ezifunwayo ngemizuzwana, inike ubucwebe ubuhle obukhethekileyo bomzobo wesiko.Ukumakishwa kweLaser kwamkela inkqubo yokumakisha engaqhagamshelwanga, esebenzisa i-laser-high-energy-density laser beam ukuze ikhuphe i-irradiate ebusweni bezinto eziphathekayo ukuze ikhuphe imathiriyeli yomphezulu okanye ivelise ukusabela kweekhemikhali ze-discoloration, ngaloo ndlela ishiya amanqaku ahlala njalo.Yonke inkqubo yokukrola ayinakho ukunxibelelana ngokuthe ngqo kunye nobucwebe, akukho friction ngoomatshini, kwaye akukho monakalo kwizacholo.Ukongeza, indawo ye-laser incinci, ukothuka kwe-thermal kuncinci, kwaye iimpawu eziphawulweyo zigqwesile kwaye akukho monakalo kubucwebe.

Ixesha lokuposa: Jun-29-2023