Umda wosetyenziso lweoomatshini bokuwelda laseriya isiba banzi ngakumbi nangakumbi, kodwa iimfuno nazo ziya zisanda ngokunyuka.Ngethuba lenkqubo ye-welding, i-gas yokukhusela kufuneka ivuthelwe ukuqinisekisa ukuba umphumo we-welding wemveliso uhle.Ke indlela yokusebenzisa ukuvuthela ngokuchanekileyo kwinkqubo yentsimbi ye-laser welding?

Kwi-laser welding, i-gas yokukhusela igesi ichaphazela ukubunjwa kwe-weld, umgangatho we-weld, ukungena kwe-weld kunye nobubanzi, njl. Kwiimeko ezininzi, ukuvuthela igesi yokukhusela kuya kuba nefuthe elihle kwi-weld, kodwa kunokuba nefuthe elibi xa lisetyenziswe ngokungalunganga.

Isiphumo esihle sokukhusela irhasiumatshini welding laser:

1. Ukuvuthela ngokuchanekileyo igesi ekhuselayo kunokukhusela ngokufanelekileyo i-weld pool ukunciphisa i-oxidation, okanye ukuphepha ukuba i-oxidized.

2. Inokunciphisa ngokufanelekileyo i-spatter eyenziwe kwinkqubo ye-welding, kwaye idlale indima yokukhusela isibuko sokugxila okanye isibuko sokukhusela.

3. Inokukhuthaza ukusasazeka kwe-uniform ye-weld pool xa iqina, ukwenzela ukuba i-weld ifane kwaye ihle.

4. Unokunciphisa ngokufanelekileyo i-weld pores.

Ngethuba nje uhlobo lwegesi, izinga lokuhamba kwegesi kunye nendlela yokuvuthela ikhethwe ngokuchanekileyo, umphumo ofanelekileyo unokufumaneka.Nangona kunjalo, ukusetyenziswa ngokungafanelekanga kwegesi yokukhusela kunokuba nemiphumo emibi kwi-welding.

Iziphumo ezibi zokusetyenziswa ngokungafanelekanga kwerhasi yokukhusela kwi-laser welding:

1. Ukunyuswa okungafanelekanga kwerhasi ekhuselayo kunokubangela i-welds embi.

2. Ukukhetha uhlobo olungalunganga lwegesi kunokubangela iintanda kwi-weld kwaye kunokubangela ukuba kuncitshiswe iimpawu zomatshini we-weld.

3. Ukukhetha isantya sokuvuthuza kwerhasi engalunganga kunokukhokelela kwi-oxidation enzulu ye-weld (nokuba isantya sokuhamba sikhulu kakhulu okanye sincinci kakhulu), okanye kunokubangela ukuba i-weld pool yesinyithi iphazamiseke kakhulu ngamandla angaphandle, okubangela ukuba weld ukudilika okanye ukwenza ngokungalinganiyo.

4. Ukukhetha indlela engafanelekanga yokuvuthela igesi kuya kubangela ukuba i-weld ingaphumeleli ukuphumeza okanye ingabi nayo impembelelo yokukhusela okanye ibe nefuthe elibi kwi-weld formation.

Uhlobo lwegesi ekhuselayo:

Isetyenziswa ngokuqhelekileyowelding laseriigesi ezikhuselayo ziyi-N2, Ar, He, kunye neempawu zabo zomzimba kunye neekhemikhali zahlukile, ngoko ke umphumo we-weld uhlukile.

Argon

Amandla e-ionization ye-Ar aphantsi kakhulu, kwaye iqondo le-ionization phantsi kwesenzo se-laser liphezulu kakhulu, elingenakukwazi ukulawula ukubunjwa kwamafu e-plasma, kwaye kuya kuba nefuthe elithile ekusebenziseni ngokufanelekileyo i-laser.Nangona kunjalo, umsebenzi we-Ar uphantsi kakhulu, kwaye kunzima ukuphendula ngeekhemikhali ngeentsimbi eziqhelekileyo.ukuphendula, kunye neendleko ze-Ar aziphezulu.Ukongeza, ubuninzi be-Ar bukhulu, obunceda ukutshona phezulu kwi-weld pool, enokukhusela ngcono i-weld pool, ngoko inokusetyenziswa njengegesi yokukhusela eqhelekileyo.

Nitrogen N2

Amandla e-ionization ye-N2 iphakathi, iphezulu kune-Ar, kwaye iphantsi kunaleyo ye-He.Ngaphantsi kwesenzo se-laser, idigri ye-ionization yi-avareji, enokunciphisa ngcono ukubunjwa kwelifu leplasma, ngaloo ndlela ikhulise ukusetyenziswa okusebenzayo kwelaser.I-nitrojeni inokusabela ngeekhemikhali kunye ne-aluminium alloy kunye nentsimbi ye-carbon kwiqondo lobushushu elithile ukuvelisa i-nitrides, eya kwandisa i-brittleness ye-weld kunye nokunciphisa ukuqina, okuya kuba nefuthe elibi kakhulu kwiipropati zomatshini we-weld joint, ngoko ke akukhuthazwa ukusebenzisa initrogen.I-aluminium alloy kunye ne-carbon steel welds zikhuselwe.I-nitride eveliswa yi-chemical reaction phakathi kwe-nitrogen kunye nensimbi engenasici inokuphucula amandla e-weld joint, eya kunceda ukuphucula iimpawu ze-mechanical weld, ngoko ke i-nitrogen ingasetyenziselwa igesi yokukhusela xa i-welding steel stainless steel.

Helium Yena

Unamandla aphezulu e-ionization, kwaye idigri ye-ionization iphantsi kakhulu phantsi kwesenzo se-laser, enokulawula kakuhle ukubunjwa kwefu le-plasma.Yigesi elungileyo yokukhusela i-weld, kodwa ixabiso likaYe liphezulu kakhulu.Ngokuqhelekileyo, le gesi ayisetyenziswa kwiimveliso eziveliswe ngobuninzi.Ngokuqhelekileyo isetyenziselwa uphando lwezenzululwazi okanye iimveliso ezinexabiso eliphezulu kakhulu elongezelelweyo.

Kukho iindlela ezimbini zokuvuthela eziqhelekileyo zokukhusela irhasi: ukuvuthela ecaleni kweshaft kunye nokuvuthela ngecoaxial.

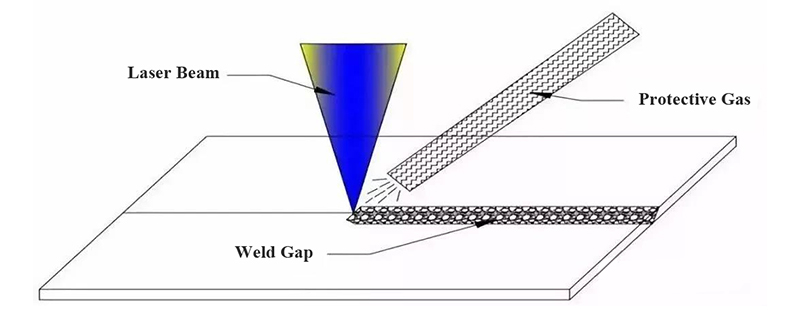

Umzobo 1: Ukuvuthela kwe-Side-shaft

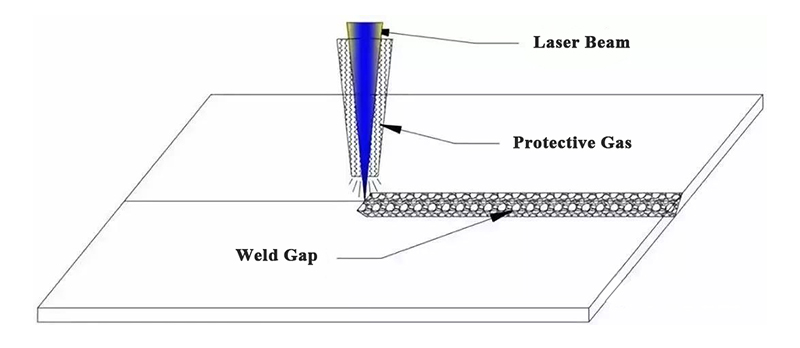

Umzobo 2: Ukuvuthela kweCoaxial

Indlela yokukhetha iindlela ezimbini zokuvuthela kukuqwalaselwa ngokubanzi.Ngokuqhelekileyo, kucetyiswa ukuba kusetyenziswe indlela yokukhusela igesi esecaleni.

Umgaqo okhethiweyo wokukhusela indlela yokuvuthela igesi: kungcono ukusebenzisa i-paraxial kwi-welds yomgca othe ngqo, kunye ne-coaxial ye-plane evaliweyo yemizobo.

Okokuqala, kufuneka kucace ukuba into ebizwa ngokuba yi "oxidation" ye-weld kuphela igama eliqhelekileyo.Kwithiyori, kuthetha ukuba i-weld iphendulwa ngamachiza kunye namacandelo ayingozi emoyeni, okubangela ukuwohloka komgangatho we-weld.Kuqhelekile ukuba i-weld metal ikwiqondo lokushisa elithile.Isabela ngokwekhemikhali kunye neoksijini, initrogen, ihydrogen, njl.njl emoyeni.

Ukuthintela i-weld ekubeni "i-oxidized" kukunciphisa okanye ukuthintela amacandelo ayingozi ukuba adibane nentsimbi ye-weld kumaqondo aphezulu okushisa, kungekhona nje isinyithi esityhidiweyo sechibi, kodwa ukususela ngexesha lokunyibilika kwentsimbi de i-pool metal iqina. kwaye ubushushu bayo behla ngaphantsi kobushushu obuthile ekuhambeni kwexesha.

Umzekelo, ukuwelda kwe-titanium alloy kunokufunxa ngokukhawuleza i-hydrogen xa ubushushu bungaphezu kwama-300 °C, ioksijini inokufunxeka ngokukhawuleza xa ubushushu bungaphezu kwama-450 °C, kwaye initrogen inokufunxwa ngokukhawuleza xa ingaphezulu kwama-600 °C, ngoko ke i-titanium I-alloy weld iqinisiwe kwaye ubushushu buyancipha ukuya kwi-300 ° C Ezi zigaba zilandelayo kufuneka zikhuselwe ngokufanelekileyo, ngaphandle koko ziya kuba "zixutywe".

Akunzima ukuqonda kule nkcazo ingentla ukuba igesi ekhuselayo evuthelweyo ayifuni kuphela ukukhusela i-weld pool ngexesha elifanelekileyo, kodwa kufuneka ikhusele indawo ethe yaqina esele idityanisiwe, ngoko ngokubanzi icala le-shaft side. kuboniswe kuMfanekiso 1 kusetyenziswa.Vuthela igesi ekhuselayo, kuba uluhlu lokukhusela lwale ndlela lubanzi kunolo lwendlela yokukhusela i-coaxial kwi-Figure 2, ngakumbi indawo apho i-weld isanda kuqina inokukhusela okungcono.

Kwizicelo zobunjineli, ayizizo zonke iimveliso ezinokusebenzisa irhasi esecaleni evuthela igesi ekhuselayo.Kwezinye iimveliso ezithile, kuphela i-coaxial shielding gas ingasetyenziselwa, ekufuneka iqhutywe kwisakhiwo semveliso kunye nefom edibeneyo.Ukhetho ekujoliswe kulo.

Ukukhethwa kweendlela ezikhethekileyo zokuvuthela irhasi yokhuseleko:

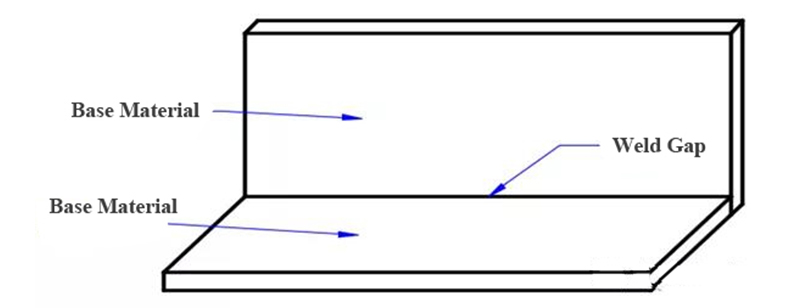

1. IiWelds ezithe ngqo

Njengoko kubonisiwe kwi-Figure 3, imilo ye-welding seam yemveliso ngumgca othe tye, kwaye ifom edibeneyo idibeneyo ye-butt, i-lap joint, i-joint yekona yangaphakathi yekona okanye i-lap welded joint.Kungcono ukuvuthela igesi ekhuselayo kwicala le-shaft.

Umzobo 3: IiWelds ezithe ngqo

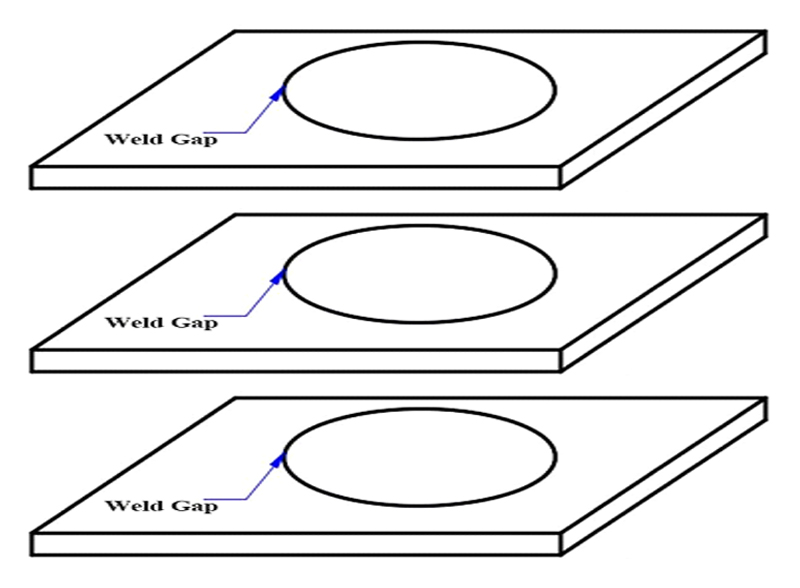

2. Iiweld zegraphic ezivaliweyo

Njengoko kuboniswe kwi-Figure 4, ubume bomthungo we-welding wemveliso bubume obuvaliweyo njengesangqa sendiza, i-polygon yendiza, kunye ne-plane ye-multi-segment line.Kungcono ukusebenzisa indlela yegesi yokukhusela i-coaxial eboniswe kuMfanekiso 2.

Umzobo 4: IiWelds zeMzobo ezivaliweyo zeFlat

Ukukhethwa kwegesi yokukhusela kuchaphazela ngokuthe ngqo umgangatho, ukusebenza kakuhle kunye neendleko zokuvelisa i-welding.Nangona kunjalo, ngenxa yokwahlukahlukana kwezixhobo ze-welding, ukukhethwa kwegesi ye-welding kukwanzima kakhulu kwinkqubo ye-welding yangempela.Kuyimfuneko ukuba kuqwalaselwe ngokubanzi izinto zokuwelda, iindlela ze-welding, kunye nezikhundla ze-welding.Kanye kunye nesiphumo esifunekayo se-welding, kuphela ngovavanyo lwe-welding kunokukhethwa i-gas ye-welding efanelekileyo ngakumbi ukuze kuphunyezwe iziphumo ezingcono ze-welding.

Ixesha lokuposa: May-08-2023