Ukucocwa kweLaser kungasetyenziswa kuphela ukucoca izinto ezingcolisa izinto eziphilayo, kodwa kunye nezinto ezingaphiliyo, ezibandakanya ukubola kwesinyithi, amasuntswana esinyithi, uthuli, njl. Nazi ezinye izicelo ezisebenzayo.Ezi teknoloji zikhulile kakhulu kwaye zisetyenziswe ngokubanzi.

1. Ukucoca ukungunda:

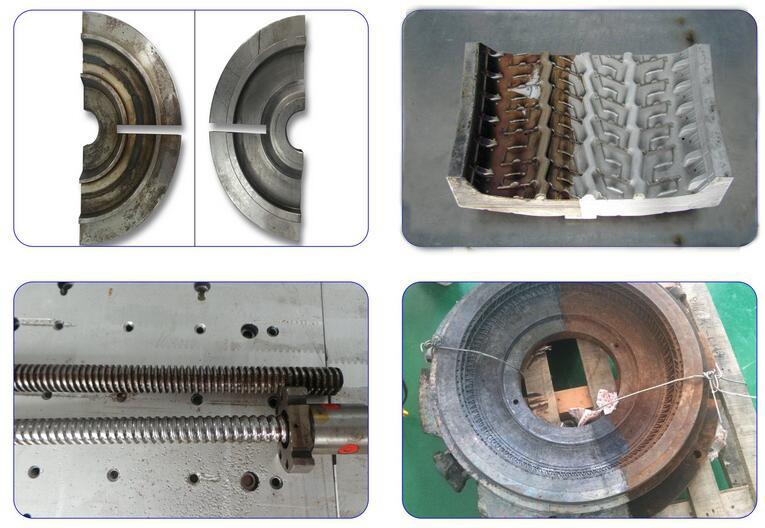

Nyaka ngamnye, ehlabathini lonke abenzi bamatayara benza amakhulu ezigidi zamatayara.Ukucocwa kwesikhunta samatayara ngexesha lenkqubo yokuvelisa kufuneka kukhawuleze kwaye kuthembeke ukonga ixesha lokuphumla.Iindlela zokucoca eziqhelekileyo ziquka i-sandblasting, i-ultrasonic okanye i-carbon dioxide yokucoca, njl., Kodwa ezi ndlela zihlala zifanele ukupholisa isikhunta esitshisa kakhulu kwiiyure ezininzi, kwaye emva koko siyihambise kwisixhobo sokucoca ukucoca.Kuthatha ixesha elide ukucoca kwaye kulula ukulimaza ukuchaneka kwesikhunta., Izinyibilikisi zeMichiza kunye nengxolo nazo zinokubangela ukhuseleko kunye nemiba yokukhuselwa kwendalo.Ukusebenzisa indlela yokucoca i-laser, kuba i-laser inokudluliselwa nge-fiber optical, iguquguqukayo ekusebenziseni;ngenxa yokuba indlela yokucoca i-laser inokudibaniswa kwi-fiber optical, isikhokelo sokukhanya sinokucocwa kwikona efileyo yesikhunta okanye inxalenye engelula ukuyisusa, ngoko kulungele ukuyisebenzisa;Akukho gasification, ngoko akukho gesi enetyhefu iya kuveliswa, eya kuchaphazela ukhuseleko lwendawo yokusebenza.Itekhnoloji ye-laser yokucoca i-mold tayara isetyenziswe ngokubanzi kwishishini lamatayara eYurophu nase-United States.Nangona ixabiso lokuqala lotyalo-mali liphezulu kakhulu, izibonelelo zokonga ixesha elilindileyo, ukuphepha ukonakaliswa kokungunda, ukhuseleko lokusebenza kunye nokugcina imathiriyeli ekrwada zinokufumaneka ngokukhawuleza.Ngokovavanyo lokucoca olwenziwa sisixhobo sokucoca i-laser kumgca wemveliso yenkampani yamatayara, kuthatha iiyure ezi-2 kuphela ukucoca iseti yesikhunta esikhulu samatayara elori kwi-Intanethi.Xa kuthelekiswa neendlela eziqhelekileyo zokucoca, iinzuzo zoqoqosho ziyabonakala.

Umaleko wefilimu ochasene nokuncamathelisa kumngundo weshishini lokutya kufuneka utshintshwe rhoqo ukuze kuqinisekiswe ucoceko.Ukucoca i-Laser ngaphandle kwee-reagents zeekhemikhali kukwafanelekile ngokukodwa kwesi sicelo.

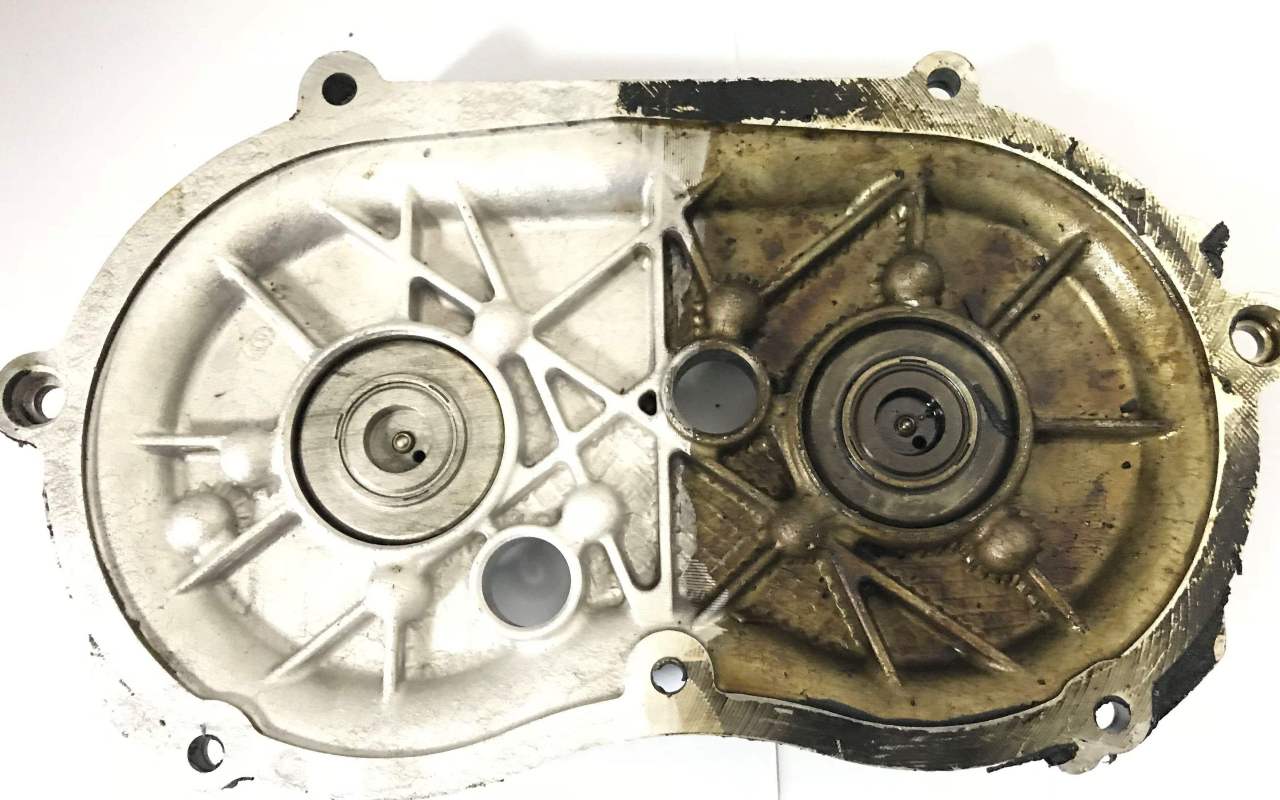

2. Ukucocwa kwezixhobo kunye nezixhobo:

Itekhnoloji yokucoca iLaser isetyenziswa kakhulu ekugcinweni kwezixhobo.Inkqubo yokucoca i-laser inokususa i-rust kunye nokungcola ngokufanelekileyo kwaye ngokukhawuleza, kwaye inokukhetha iindawo zokucoca ukuze ziqonde ukuzenzekelayo kokucoca.Ukusebenzisa ukucocwa kwe-laser, kungekhona nje ukucoceka okuphezulu kunenkqubo yokucoca imichiza, kodwa kwakhona phantse akukho monakalo kumphezulu wento.Ngokumisela iiparitha ezahlukeneyo, ifilimu ekhuselweyo ye-oxide exineneyo okanye umaleko wesinyithi onyibilikisiweyo unokuqulunqwa kumphezulu wento yentsimbi ukuphucula amandla omhlaba kunye nokumelana nokubola.Inkunkuma ekhutshwe yi-laser ngokusisiseko ayingcolisi indalo, kwaye inokuthi iqhutywe kude, ngokufanelekileyo ukunciphisa umonakalo wezempilo kumqhubi.

3.Ukususwa kwepeyinti yenqwelomoya endala:

Iinkqubo zokucoca iLaser kudala zisetyenziswa kushishino lwenqwelomoya eYurophu.Umphezulu wenqwelo-moya kufuneka upeyintwe kwakhona emva kwexesha elithile, kodwa ipeyinti endala kufuneka isuswe ngokupheleleyo phambi kokupeyintwa.Indlela yesithethe yokususa ipeyinti yomatshini inokwenza lula umonakalo kumphezulu wesinyithi wenqwelomoya kwaye izise iingozi ezifihlakeleyo kwinqwelomoya ekhuselekileyo.Ukuba iinkqubo ezininzi zokucoca ngelaser zisetyenziswa, ipeyinti engaphezulu kweA320 Airbus inokususwa ngokupheleleyo kwiintsuku ezimbini ngaphandle kokonakalisa umphezulu wesinyithi.

4.Ukucoca kwishishini lombane

Ishishini le-electronics lisebenzisa iilaser ukususa i-oxides: Ishishini le-elektroniki lifuna ukucocwa okuphezulu kokucocwa, kwaye iilaser zilungele ukususwa kwe-oxide.Ngaphambi kokuba ibhodi yesekethe ithengiswe, izikhonkwane zecandelo kufuneka zihlanjululwe ngokucokisekileyo ukuze kuqinisekiswe uqhagamshelwano olungcono kakhulu lombane, kwaye izikhonkwane akufanele zonakaliswe ngexesha lenkqubo yokucoca.Ukucocwa kweLaser kunokuhlangabezana neemfuno zokusetyenziswa, kwaye ukusebenza kakuhle kuphezulu kakhulu, i-stitch enye kuphela ye-laser i-irradiated.

5.Ukucocwa kokuchithwa kwe-deesterification ngokuchanekileyo kushishino loomatshini oluchanekileyo:

Umzi-mveliso woomatshini abachanekileyo uhlala ufuna ukususa ii-esters kunye nee-oyile zeminerali ezisetyenziselwa ukuthambisa kunye nokuxhathisa ukubola kumalungu, ngokwesiqhelo ngeendlela zeekhemikhali, kwaye ukucocwa kweekhemikhali kuhlala kuneentsalela.I-laser deesterification inokususa ngokupheleleyo i-esters kunye neoli ye-mineral ngaphandle kokonakalisa umphezulu wenxalenye.Ukususwa kwezinto ezingcolisayo kugqitywe ngamaza othusayo, kunye nokuqhuma kwe-gasification yomgangatho obhityileyo we-oxide kumphezulu weendawo zenza i-wave shock wave, ekhokelela ekususweni kokungcola endaweni yokusebenzisana komatshini.Izinto eziphathekayo zisuswe ngokupheleleyo kwaye zisetyenziselwa ukucocwa kweendawo zoomatshini kwishishini le-aerospace.Ukucocwa kweLaser kungasetyenziselwa ukususa ioli kunye ne-ester ekuqhutyweni kwamalungu omatshini.

Ixesha lokuposa: Jan-11-2022