Ukuwelda kweLaser bubuchule bokuwelda obusetyenziselwa ukudibanisa iziqwenga ezininzi zetsimbi ngokusebenzisa umqadi welaser.Inkqubo ye-laser welding ibonelela ngomthombo wokushisa ogxininisiweyo, ovumela i-welds emxinwa, enzulu kunye namazinga aphezulu e-welding.Le nkqubo isetyenziswa rhoqo kwizicelo ze-welding eziphezulu, ezifana ne-Automotive Industry.

I-laser welding iyayikhawulezisa inkqubo yokutshintsha iindawo ezibunjiweyo ezinesitampu.I-laser welding isetyenziselwa ukubuyisela i-discrete welds kunye ne-laser welds eqhubekayo, enokunciphisa ububanzi obudlulayo kunye nezinye iindawo ezomelezayo, kwaye inokucinezela umthamo wesakhiwo somzimba ngokwawo.Ngenxa yoko, ubunzima bomzimba wesithuthi bunokuncitshiswa nge-56kg.Ukusetyenziswa kwe-laser welding kuphumelele ukunciphisa ubunzima kunye nokunciphisa ukukhutshwa, okuhlangabezana neemfuno zokukhuselwa kwendalo kwixesha lanamhlanje.

I-Laser welding isetyenziselwa ukuthunga i-welding yeepleyiti ezinobunzima obungalinganiyo, kwaye izibonelelo zibaluleke kakhulu.Le teknoloji iguqula inkqubo yemveli yokuvelisa-okokuqala ukunyathela kwiindawo, kwaye emva koko i-welding ibe yinto epheleleyo: okokuqala ukuwelda iindawo ezininzi ezinobunzima obuhlukeneyo buphelele, kwaye emva koko ugxininise kwaye wenze, ukunciphisa inani lamalungu kunye nokusebenzisa izinto ezininzi.Ingqiqo, isakhiwo kunye nomsebenzi ziphuculwe kakhulu.

Iindlela ezahlukeneyo zokuwelda i-laser zihlala zisetyenziselwa ukuwelda amalungu ahlukeneyo omzimba.Oku kulandelayo luhlu lweendlela ezininzi ze-laser welding ezisetyenziswa rhoqo kushishino lweemoto.

(1) Ukunyanyiswa kwelaser

I-Laser brazing isetyenziselwa ukudibanisa kwekhava ephezulu kunye nodonga olusecaleni, isivalo se-trunk, njl. I-Volkswagen, i-Audi, i-Peugeot, i-Ford, i-Fiat, i-Cadillac, njl.

(2) Laser self-fusion welding

I-laser self-fusion welding yeyokuwelda kokungena nzulu, esetyenziselwa ikakhulu uphahla kunye neepaneli ezisecaleni, iingcango zemoto, njl.

(3) Laser ukuwelda kude

I-laser ye-welding ekude isebenzisa irobhothi + galvanometer, indawo ekude ye-beam + i-welding, kwaye inzuzo yayo ikukunciphisa kakhulu ixesha lokubeka kunye nokusebenza okuphezulu xa kuthelekiswa nokusetyenzwa kwelaser yesiko.

I-laser welding ingasetyenziswa kwi-cigar lighter, i-valve lifter, i-cylinder gaskets, i-injection fuel, i-spark plugs, i-gear, i-shafts esecaleni, i-shafts ye-drive, i-radiator, i-clutches, i-injini yokukhupha imibhobho, i-axles ye-supercharger, kunye nokulungiswa kwe-airbag liner kunye nokudityaniswa kwemoto eyonakeleyo. iinxalenye.

I-laser welding ineengenelo ezininzi kunye neenzuzo ngaphezulu kweendlela zemveli zokuwelda kwaye inokunciphisa kakhulu iindleko ngelixa iphucula impumelelo kunye nomgangatho wemveliso.

I-laser welding inezi mpawu zilandelayo:

①Uluhlu lokufudumeza olumxinwa (lugxininise).

②Indawo yentshukumo kunye nendawo zilawuleka ngokuchanekileyo.

③Izowuni echatshazelwe bubushushu incinci.

④I-welding deformation incinci, kwaye akukho lungiso lwe-post-welding olufunekayo.

⑤ Ukusingathwa koqhagamshelwano, akukho mfuneko yokucinezela i-workpiece kunye nonyango lwangaphandle.

⑥Inokuqonda ukuwelda kwemathiriyeli eyahlukileyo.

⑦ Isantya se-welding sikhawuleza.

⑧ Akukho mpembelelo yobushushu, akukho ngxolo kwaye akukho ngcoliseko kwihlabathi langaphandle.

Oomatshini abacetyiswayo abalungele i-welding auto zezi zilandelayo:

Umatshini wokuwelda weLaser weMold

Ngophuhliso lweshishini, itekhnoloji ye-laser welding ihlala iphandwa kwaye ihlaziywa.Okwangoku, kushishino lwe-welding mechanical, umatshini we-laser welding othandwayo ngenxa yeempawu ezibalaseleyo zokusebenza kwaye ubonisa iimpawu zenkqubo efanelekileyo ngexesha lenkqubo ye-welding.Ngoko inokusetyenziswa ngokubanzi kwiinkalo ezininzi.

Ukubumba kwi-mold laser welding idlala indima ebaluleke kakhulu kumashishini anamhlanje, kwaye umgangatho wayo uchaza ngokuthe ngqo umgangatho wemveliso.Ukuphucula ubomi benkonzo kunye nokuchaneka kwesikhunta kunye nokunciphisa umjikelo wokwenziwa kwesikhunta ziingxaki zobuchwepheshe ekufuneka iinkampani ezininzi zizisombulule ngokukhawuleza.Nangona kunjalo, iindlela zokungaphumeleli ezinje ngokuwa, ukuguqulwa, ukunxiba, kunye nokuqhekeka zihlala zisenzeka ngexesha lokusetyenziswa kwesikhunta.Ke ngoko, iteknoloji yokulungisa i-laser welding nayo iyimfuneko ekulungiseni ukungunda.

Umatshini wokuwelda weLaser luhlobo olutsha lwendlela yokuwelda, ngakumbi ukuwelda kwezinto ezinodonga olubhityileyo kunye namalungu achanekileyo.Inokuqonda i-welding, i-butt welding, i-stitch welding, i-welding yokutywina, njl.Incinci, i-deformation encinci, isantya se-welding ekhawulezayo, i-welding seam egudileyo kunye nenhle, akukho mfuneko okanye ukusetyenzwa okulula emva kwe-welding, umgangatho we-welding ephezulu, akukho mingxunya yomoya, ulawulo oluchanekileyo, indawo encinci yokugxila, ukuchaneka kokuma okuphezulu, kunye nokulula ukuyiqonda i-automation.

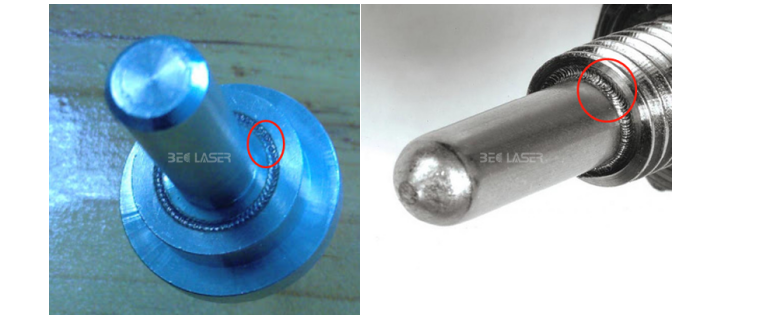

Umzekelo oqhelekileyo wokusetyenziswa kwe-laser welding kwishishini lokubumba ngumatshini wokulungisa i-laser welding.Esi sixhobo silula kubaqhubi ukuba basebenzise, sinokunyusa kakhulu isantya sokulungiswa kwe-welding, kwaye umphumo wokulungisa kunye nokuchaneka kusondele kubuhle, okwenza izixhobo Isetyenziswe ngokubanzi kwintsimi ye-mold welding.Ukulungiswa kwe-welding ubushushu kwindawo echaphazelekayo yalo matshini wokuwelda incinci kakhulu, kwaye ayifuni ukufudumeza kwangaphambili, kwaye i-workpiece edibeneyo ayibonakali i-annealing phenomenon emva komsebenzi.Le teknoloji yokulungisa i-laser i-welding ayinakusetyenziselwa kuphela ukulungisa ukunxitywa kwe-mold, kodwa inokufezekisa ukuwelda okuchanekileyo kwamalungu omzimba ahlukeneyo.

Ixesha lokuposa: Jul-15-2021