Ngoku,oomatshini bokuwelda laserzisetyenziswe ngokubanzi ukuhlobisa intengiso, ubucwebe, iingcango kunye neefestile kunye namanye amashishini.Yintoni umahluko phakathi kwe-laser welding kunye ne-argon arc welding, i-soldering kunye nobunye ubuchwepheshe be-welding yendabuko?Yintoni eyenza iumatshini welding laserukuthembela ekubeni ngokuthe ngcembe ube yeyona nto iphambili yetekhnoloji ye-welding yangoku?

Umatshini wokuwelda weLaserluhlobo olutsha lwendlela yokuwelda, ingakumbi ukuwelda kwezixhobo ezibhityileyo kunye namalungu amahle, anokugqiba ukuwelda, i-butt welding, i-stitch welding, i-welding yokutywina, njl njl. i-welding seam enhle, akukho mfuneko okanye unyango olulula kuphela emva kwe-welding, umgangatho ophezulu we-welding seam, akukho pores, ulawulo oluchanekileyo, indawo encinci yokukhanya, ukuchaneka kokubeka okuphezulu, kulula ukugqiba ukuzenzekelayo.Isebenzisa i-high-energy laser pulses ukufudumeza ngokuyinxenye izinto kwindawo encinci.Amandla emitha yelaser asasazeke kwizinto ngokuqhutywa kobushushu, anyibilikise imathiriyeli ukwenza ichibi elithile elinyibilikisiweyo, emva koko anyibilikise ezi zinto zimbini zidibana kunye.

Indlela i-laser welding isebenza ngayo

Ukuwelda kweLaser kukukhanyisa umqadi we-laser ophezulu kakhulu kumphezulu wesinyithi, kwaye ngokusebenzisa intsebenziswano phakathi kwe-laser kunye nesinyithi, isinyithi siyanyibilika ukuze senze i-weld.Ukunyibilika kwesinyithi yinto enye kuphela yezinto ezibonakalayo ngexesha lokusebenzisana kwe-laser kunye nesinyithi.Ngamanye amaxesha amandla okukhanya awaguqulwa kakhulu abe yintsimbi yokunyibilika, kodwa abonakaliswe kwezinye iifom, ezifana ne-vaporization, ukwakheka kweplasma, njl.Ukuza kuthi ga ngoku, kuyafuneka ukuba uqonde izinto ezahlukeneyo zomzimba ezenziwe kunxibelelwano phakathi kwe-laser kunye nentsimbi kunye nobudlelwane phakathi kwezi ziganeko ezibonakalayo kunye neeparamitha ze-laser, ukuze uninzi lwamandla e-laser lube nokulawulwa ngokulawula iiparamitha ze-laser.

Iguqulwa ibe amandla okunyibilika kwesinyithi ukufezekisa injongo ye-welding.

Iiparamitha zenkqubo ye-laser welding

1.Ukuxinana kwamandla

Uxinaniso lwamandla yenye yezona parameters zibaluleke kakhulu kwi-laser processing.Ngoxinaniso lwamandla aphezulu, umaleko womphezulu unokufudunyezwa kwindawo yokubilisa kuluhlu lwexesha le-microsecond, okukhokelela kwisixa esikhulu somphunga.Ke ngoko, uxinaniso lwamandla aphezulu luluncedo kwiinkqubo zokususa izinto ezifana nokubetha, ukusika, nokukrola.Ukuxinana kwamandla asezantsi, kuthatha iimillisecond ezininzi ukuze ubushushu bomphezulu bufike kwindawo yokubila.Ngaphambi kokuba umphezulu ube ngumphunga, umaleko ongezantsi ufikelela kwindawo yokunyibilika, ekulula ukwenza i-weld ye-fusion efanelekileyo.Ngoko ke, kwi-conduction laser welding, ubuninzi bamandla buphakathi kwe-104 ~ 106W / cm2.

2.Laser ipulse waveform

Ukumila kwe-Laser pulse ngumba obalulekileyo kwi-laser welding, ngakumbi kwi-welding sheet ebhityileyo.Xa i-laser beam ephezulu ibetha phezu kwezinto eziphathekayo, i-60 ~ 98% yamandla e-laser iya kubonakaliswa kwaye ilahleke phezu komhlaba wesinyithi, kwaye ukubonakaliswa kuyahluka kunye nobushushu bomhlaba.Ngexesha lesenzo se-laser pulse, ukubonakaliswa kweentsimbi kuyahluka kakhulu.

3.Laser pulse ububanzi

Ububanzi be-Pulse yenye yeeparameters ezibalulekileyo ze-pulse laser welding.Akuyona nje ipharamitha ebalulekileyo eyahlukileyo ekususweni kwezinto kunye nokunyibilika kwezinto, kodwa kunye nepharamitha ephambili emisela iindleko kunye nomthamo wezixhobo zokusebenza.

4. Impembelelo yexabiso le-defocus kumgangatho we-welding

Ukuwelda ngelaser kudla ngokufuna indlela ethile yokususa ugxininiso, kuba uxinaniso lwamandla kumbindi wendawo ekugxilwe kuyo ngelaser luphezulu kakhulu, kwaye kulula ukuphuphuma lungene emngxunyeni.Unikezelo loxinaniso lwamandla lufana ngokulinganayo kuzo zonke iinqwelomoya ezikude kugxininiso lwelaser.

Kukho iindlela ezimbini zokususa ugxininiso: ukugxininiswa okulungileyo kunye nokunciphisa okungalunganga.Inqwelomoya ekugxilwe kuyo ngaphezu kwendawo yokusebenza i-positive defocus, ngaphandle koko i-negative defocus.Ngokwe-geometrical optics theory, xa i-defocus ilungile, ubuninzi bamandla kwinqwelomoya ehambelanayo buphantse bufana, kodwa imilo ye-pool etyhidiweyo efunyenweyo ihluke ngokwenene.Xa i-defocus ingalunganga, ubunzulu obukhulu bokungena bunokufumaneka, obunxulumene nenkqubo yokuqulunqwa kwedama elityhidiweyo.Iimvavanyo zibonisa ukuba xa i-laser ifudunyezwa i-50 ~ 200us, i-material iqala ukunyibilika, yenze inqanaba lesinyithi kunye ne-vaporizing, yenze umphunga woxinzelelo lwentengiso, okhutshwa ngesantya esiphezulu kakhulu, ukhupha ukukhanya okumhlophe okuqaqambileyo.Kwangaxeshanye, iqondo eliphezulu lomphunga lihambisa isinyithi elulwelo kwincam yedama elinyibilikisiweyo, lenze ukudakumba kumbindi wedama elinyibilikisiweyo.Xa i-defocus ingalunganga, ubuninzi bamandla angaphakathi bezinto eziphathekayo buphezulu kunobuphezulu, kwaye kulula ukwenza ukunyibilika okunamandla kunye ne-vaporization, ukwenzela ukuba amandla okukhanya adluliselwe nzulu kwizinto eziphathekayo.Ngoko ke, kwizicelo ezisebenzayo, xa ubunzulu bokungena bufuneka ukuba bube bukhulu, kusetyenziswa ukuchithwa okungalunganga;xa welding izinto ezibhityileyo, defocusing positive kufuneka kusetyenziswe.

Xa kuthelekiswa netekhnoloji yewelding yemveli,umatshini welding laserinezi nzuzo zilandelayo

1. Inemisebenzi eyahlukeneyo epheleleyo, kwaye i-welding seam incinci, enokuthi iqonde i-welding echanekileyo;

2. Uyilo lwesakhiwo lusebenziseka lula, intloko ye-laser inokolulwa ngasemva nangaphezulu, isekhohlo nasekunene, phezulu naphantsi ngesandla, ilungele ukudityaniswa nokungadibanisi kunye nokude kwe-welding yeemveliso ezahlukeneyo;

3. Umthungo we-welding ulungile, isakhiwo se-welding siyafana, akukho pores, akukho ngcoliseko, kunye neziphene ezimbalwa zokufakwa;

4. Isantya se-welding sikhawuleza, i-aspect ratio inkulu, i-deformation incinci, kwaye ukusebenza kuzinzile, enokuqonda ukuveliswa kobunzima ngokuzenzekelayo;

4.Luhlobo olutsha lwendlela ye-welding.Ukuwelda kweLaser kujoliswe ikakhulu ekudibaneni kwezinto ezinodonga olubhityileyo kunye neenxalenye ezichanekileyo.Iyakwazi ukuqaphela i-welding, i-butt welding, i-stitch welding, i-welding yokutywina, njl. ulawulo oluchanekileyo, indawo encinci yokugxila, ukuchaneka kokuma okuphezulu, kulula ukufikelela kwi-Automation, ngoko ke ithandwa kakhulu ngabasebenzisi, ayiphuculi nje impumelelo yemveliso kunye nokusetyenzwa, kodwa ikwanciphisa umsebenzi onzima olandelayo emva kokulungiswa.

Umzi-mveliso we-laser welding

Umzi-mveliso weemoto, ishishini lokungunda, ishishini lezonyango, ishishini lobucwebe, njl.

Uhlobo lweumatshini welding laser

1.I-Fiber laser welding machine-Handheld Type

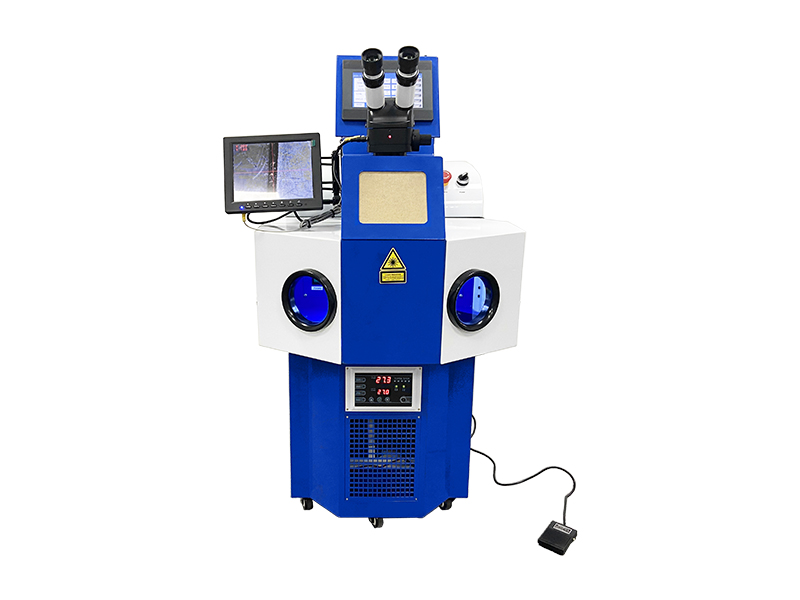

2.Umatshini we-laser welding we-mold- Uhlobo lweManuwali

3.Cantilever laser welding machine-Ngengalo eyonqenayo

4.3-Axis laser welding machine-Uhlobo oluzenzekelayo

5.Jewelry laser welding machine-Desktop Uhlobo

6.Umatshini wokuwelda welaser yobucwebe–Inbuilt Water Chiller

7.Jewelry jewelry laser welding machine-Ukwahlula Water Chiller

Iisampulu:

Ixesha lokuposa: Apr-27-2023