Kwiminyaka yakutshanje, uphuhliso lweshishini lokuvelisa luye lwakhawuleza kakhulu, kwaye imfuno yokulungiswa kwesinyithi iye yanda.I-Welding yenye yeenkqubo ezibalulekileyo zokulungisa isinyithi, kwaye iindlela zemveli ze-welding azikwazanga ukuhlangabezana neemfuno zemveliso.Ngaphantsi kwesi sizathu, iumatshini welding laser weldingyazalwa, eyanconywa ngokubanzi xa iqalisiwe, kwaye yatshintsha ngokukhawuleza imarike yemveli yokuwelda ipleyiti ebhityileyo.

Iumatshini wokuwelda ifayibha laser ngesandlasisizukulwana esitsha sezixhobo zokuwelda i-laser.Yeyokuwelda okungaqhagamshelwanga nayo.Ayifuni uxinzelelo ngexesha lokusebenza., enyibilikisa i-material ngaphakathi, kwaye emva koko ipholile kwaye ikhazimle ukwenza i-weld.

a.Akukho mandla angaphandle aya kwenziwa kwiworkpiece

Xa umatshini we-laser welding obambe ngesandla uqhuba amacandelo, kuba akayi kudibana namalungu acutshungulweyo, akuyi kubakho uxinzelelo lwangaphandle kwiindawo ezicutshungulweyo ngexesha lenkqubo yonke yokuwelda, kwaye ugxininiso lwamandla olwenziwa yilaser lukhulu kakhulu. phezulu.Impembelelo ye-thermal kwindawo ejikeleze inxalenye incinci, ngoko ke inxalenye ayiyi kuphazamiseka ngexesha le-welding.

b.Ukuwelda phakathi kwezixhobo ezahlukeneyo kunokufezekiswa

Kwinkqubo yemveli yokuwelda, ngokuqhelekileyo zimbini kuphela izinto zokusebenza ezenziwe ngezinto ezifanayo ezinokudityaniswa, kodwa inkqubo yokuwelda yelaser yomatshini wokuwelda obambe ngesandla we-laser awukwazi nje ukuwelda indawo ephezulu yokunyibilika kunye nezixhobo ezahlukeneyo ekunzima ukunyibilika kunye nokuwelda. , Njenge-titanium alloy, i-aluminium alloy kunye nezinye izinto.Ukongeza, itekhnoloji ye-laser ye-welding processing inokuqonda ukuwelda phakathi kwezinto ezingafaniyo, ukwaphula umda we-welding phakathi kwemathiriyeli.

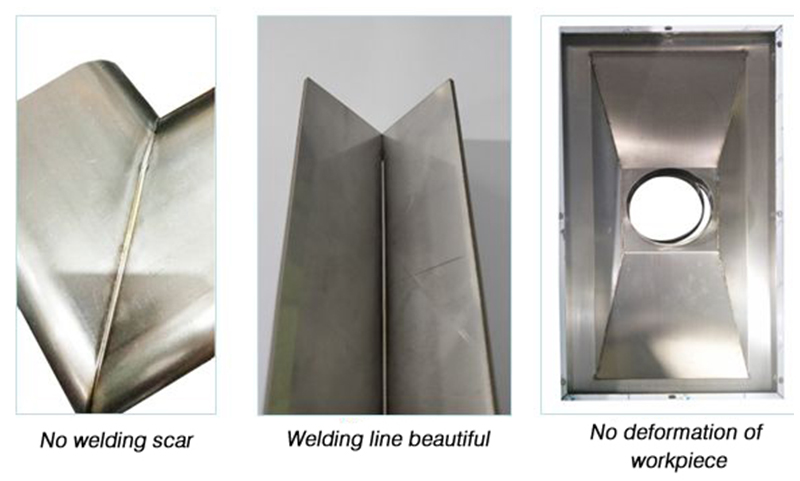

c.Umthungo we-welding encinci, ucocekile kwaye ubukeka obuhle

Itekhnoloji ye-laser yokuwelda yomatshini wokuwelda we-laser obambe ngesandla uhambele phambili kakhulu, ayingcolisi nje indawo esingqongileyo, kodwa ikwayila amalungu amancinci e-solder, i-welding seams emxinwa, i-uniform ye-welding seam structure, iipores ezimbalwa kakhulu kunye neziphene, ezinokunciphisa kwaye Ukwandisa ukungcola kwezinto zomzali, Ngoko ke, emva kwe-welding, kungekhona kuphela ukuchasana okuhlukeneyo, kodwa umphezulu wezinto eziphathekayo ucocekile kwaye uhle kakhulu.

Iimpawu zeumatshini welding laser welding:

1. Isixhobo sincinci ngobukhulu

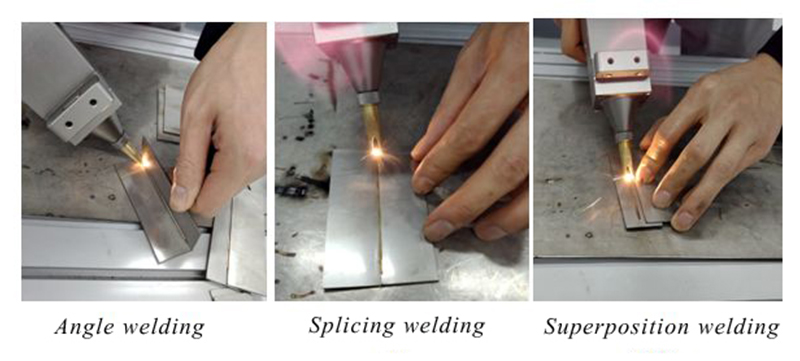

2. Ukusebenza okuguquguqukayo kunye nokufanelekileyo, kunokuqonda i-welding yangaphandle

3. Umgangatho omhle we-beam, isantya esikhawulezayo, ukuguqulwa kwe-thermal encinci, ukuchaneka kunye nokudibanisa okuphezulu

4. I-welding seam ihle, icwecwe kwaye ayinayo i-pores, kwaye akukho nyango okanye unyango olulula olufunekayo emva kwe-welding.

5. Umpu we-welding obanjwe ngesandla unokuwudibanisa i-workpiece nakweyiphi na i-angle, efanelekileyo kwi-spot welding of welds complex kunye nezixhobo ezahlukeneyo.

Izinto eziluncedo kumatshini wokuwelda welaser obambe ngesandla:

1. Ukusebenza kulula kwaye kulula ukuyisebenzisa: umatshini we-laser welding welding kulula ukuyisebenzisa kwaye uneendleko eziphantsi zabasebenzi.

2. Isantya se-welding esikhawulezayo: Umatshini we-laser welding obambe ngesandla uqhubela phambili, amandla e-beam axinene, i-welding iyasebenza kwaye i-high-speed, indawo ye-welding encinci, indawo echaphazelekayo yokushisa incinci, i-welding seam igudile. kwaye intle, kwaye inkqubo yokugaya elandelayo iyancitshiswa.

3. Izinto ezahlukahlukeneyo zokuwelda: Umatshini we-laser welding obambe ngesandla unokuwelda izinto eziqhelekileyo zetsimbi ezifana neepleyiti zentsimbi, iipleyiti zentsimbi, iipleyiti zegalvanized, kunye neepleyiti ze-aluminium.

4. Iimfuno zokusingqongileyo eziphantsi zokucwangcisa: Umshini we-laser welding welding awufuni itafile ekhethekileyo ye-welding, izixhobo zithatha indawo encinci, kwaye ukulungiswa kuyaguquguquka.Ixhotyiswe ngeemitha ezininzi zemigca yolwandiso lwefiber optical, enokuthi ihanjiswe kwimisebenzi emide ngaphandle kwemiqobo yendawo yokusingqongileyo.

5. Umsebenzi ozinzileyo: I-laser ixhotyiswe ngezixhobo zokupholisa amanzi, ezinokuqinisekisa umsebenzi oqhubekayo ophezulu.

6. Ukusebenza kweendleko eziphezulu: Umshini we-laser welding welding awukwazi nje ukwenza imisebenzi ye-welding, kodwa uphinde ulungise i-molds.Ubomi be-laser ziiyure ezingama-100,000, ubude kakhulu kunobomi benkonzo yezixhobo eziqhelekileyo, kwaye zibiza kakhulu.

Ukuthelekiswa kokusetyenziswa kwamandla phakathiumatshini welding laser weldingkunye ne-argon arc welding:

Xa kuthelekiswa ne-arc welding yendabuko, umatshini we-laser welding obambe ngesandla ugcina malunga ne-80% ukuya kwi-90% yamandla ombane, kwaye iindleko zokucubungula zingancitshiswa malunga ne-30%.Ukuthelekisa umphumo we-Welding: umatshini we-laser welding obambe ngesandla unokugqiba isinyithi esingafaniyo kunye nentsimbi yentsimbi.Isantya esikhawulezayo, i-deformation encinci kunye nobushushu obuncinci bommandla ochaphazelekayo.Iiweld zintle, zisicaba, kwaye azinabo/zincinci.I-laser ebanjwa ngesandla yamacandelo amancinci avulekileyo kunye ne-welding.Ukuthelekisa inkqubo elandelayo: Umatshini we-laser welding wesandla unegalelo eliphantsi lokushisa kunye ne-deformation encinci ye-workpiece ngexesha le-welding, kwaye unokufumana indawo ye-welding enhle ngaphandle okanye unyango olulula kuphela (kuxhomekeke kwiimfuno ze-welding surface effect).Umatshini we-laser welding obambe ngesandla unokunciphisa kakhulu iindleko zabasebenzi zenkqubo enkulu yokupolisha kunye nenqanaba.

Iinkalo zesicelo zomatshini wokuwelda welaser obanjwe ngesandla:

Ngokukodwa kwindawo esisigxina yentsimbi enkulu kunye nephakathi, ikhabhinethi, i-chassis, umnyango we-aluminium kunye nefreyimu yefestile, isitya sokuhlamba isinyithi esingenasici kunye nezinye izinto zokusebenza ezinkulu ezifana ne-angle yangaphakathi yasekunene, i-angle yangaphandle yasekunene, i-weld welding ye-plane, ubushushu obuncinci buchaphazelekayo. indawo ngexesha le-welding, i-deformation encinci, kunye nobunzulu be-welding Enkulu kwaye iqiniswe ngokuqinileyo.Isetyenziswa ngokubanzi kwishishini lekhitshi kunye negumbi lokuhlambela, ishishini lezixhobo zasekhaya, ishishini lentengiso, ishishini lokubumba, ishishini lemveliso yensimbi engenasici, ishishini lobunjineli bensimbi engenasici, ishishini lomnyango kunye nefestile, ishishini lezandla, ishishini lemveliso yasekhaya, ishishini lefenitshala, ishishini lezixhobo zemoto, njl.

Ukusetyenziswa kunye nobukrelekrele beoomatshini bokuwelda laserbaye baba sisixhobo esinamandla kwizixhobo zoshishino.Ukusebenza okuphezulu kokusebenza kunye neempawu ezigqwesileyo zokusetyenzwa kwezixhobo ze-laser welding ngesandla zenze igalelo eliphezulu kwimveliso yamashishini amakhulu., ikwalukhetho lwezityalo ezininzi zokulungisa.

Ixesha lokuposa: May-10-2023