Umatshini wokuwelda weLaserluhlobo lwezixhobo zokuwelda eziqhele ukusetyenziswa kwimveliso yemizi-mveliso, kwaye ikwangumatshini oyimfuneko wokusetyenzwa kwemathiriyeli yelaser.Oomatshini bokuwelda beLaser baye bakhula ngokuthe ngcembe ukusuka kuphuhliso lokuqala ukuza kuthi ga ngoku, kwaye iintlobo ezininzi zoomatshini bokuwelda ziye zafunyanwa.

Ukuwelda kweLaser luhlobo olutsha lwendlela yokuwelda kunye nenye yeenkalo ezibalulekileyo zokusetyenziswa kobuchwepheshe bokucwangcisa izinto.Ukuwelda kweLaser kujoliswe ikakhulu ekudibaneni kwezinto ezinodonga olubhityileyo kunye neenxalenye ezichanekileyo.Inkqubo yokuwelda yeyohlobo lokuqhuba ubushushu, oko kukuthi, umphezulu we-workpiece ufudunyezwe yimitha yelaser, kwaye ubushushu bomhlaba budlula. iiparamitha zokulawula ezifana nobubanzi, amandla, amandla aphezulu kunye nokuphindaphinda okuphindaphindiweyo kwe-laser pulse.Iyakwazi ukuqaphela i-welding yendawo, i-welding ye-butt, i-stitch welding, i-welding ye-welding, njl. kwaye akukho nyango okanye unyango olulula olufunekayo emva kwe-welding.I-welding seam ikumgangatho ophezulu, ayinayo i-pores, inokulawulwa ngokuchanekileyo, inendawo encinci yokugxila, kwaye ineendawo eziphezulu zokuchaneka, kwaye kulula ukuzenzela.

Ukugcinwa komatshini we-laser welding:

Iumatshini welding laserifuna ukulungiswa, kwaye ubushushu betanki yamanzi kufuneka buhlengahlengiswe ebusika nasehlotyeni.Thintela ubushushu begumbi ekubeni bubanda kakhulu okanye bushushu kakhulu ukuchaphazela amandla emveliso yelaser.Kucetyiswa ukuba ulungelelanise ubushushu betanki yamanzi ukuya kwi-3 ~ 5 degrees ngaphantsi kweqondo lokushisa kwegumbi ngokweqondo lokushisa kwegumbi, elingenakuqinisekisa kuphela amandla okuphuma kwe-laser, kodwa nokuqinisekisa ukuzinza kwemveliso ye-laser.

1. Ukumiselwa kobushushu bamanzi

Ubushushu bamanzi okupholisa bunefuthe elithe ngqo kwi-electro-optical conversion performance, ukuzinza kunye ne-condensation.Kwiimeko eziqhelekileyo, ubushushu bamanzi okupholisa bubekwe ngolu hlobo lulandelayo: amanzi acocekileyo (akwabizwa ngokuba ngamanzi aphantsi-ubushushu, asetyenziselwa ukupholisa imodyuli yomatshini we-laser welding), ubushushu bamanzi besiphaluka samanzi kufuneka bubekwe ngokubanzi malunga ne-21 °C, kwaye inokusetwa ngokufanelekileyo phakathi kwe-20 kunye ne-25 °C ngokwemeko.Uhlengahlengiso.Olu hlengahlengiso kufuneka lwenziwe yingcali.

Ubushushu bamanzi bamanzi e-DI enziwe i-deionized (ekwaziwa ngokuba ngamanzi obushushu obuphezulu, asetyenziselwa ukupholisa iindawo zamehlo) kufuneka zibekwe phakathi kwe-27°C kunye ne-33°C.Eli qondo lobushushu kufuneka lihlengahlengiswe ngokweqondo lobushushu kunye nokufuma.Ukuphakama kokufuma, kokukhona ubushushu bamanzi bamanzi e-DI kufuneka bonyuke ngokufanelekileyo.Umgaqo osisiseko ngulo: Ubushushu bamanzi e-DI kufuneka bube ngaphezu kwendawo yombethe.

2. Amanyathelo okuthintela afana namacandelo angaphakathi e-elektroniki okanye optical

Eyona njongo iphambili kukuthintela ukujiya kwezixhobo zombane okanye zamehlo ngaphakathiumatshini welding laser.Qinisekisa ukuba i-chassis ayinamoya: ingaba iingcango zekhabhinethi zikhona kwaye zivaliwe ngokuqinileyo;nokuba iibholiti eziphezulu zokunyusa ziqinisiwe;ingaba ikhava yokukhusela yolawulo lonxibelelwano olungasetyenziswanga ngasemva kwe-chassis igubungele, kwaye ingaba ezi zisetyenzisiweyo zilungisiwe.Gcina umatshini we-laser welding kwaye ubeke ingqalelo kulandelelwano lokutshintsha nokucima.Faka igumbi eline-air-conditioning kumatshini we-laser welding, uvule umsebenzi we-air-conditioning dehumidification kwaye ugcine i-air-conditioning isebenza ngokuqhubekayo kunye nokuzinza (kubandakanywa ebusuku), ukwenzela ukuba ubushushu kunye nomswakama kwigumbi eline-air-conditioning zigcinwe. I-27 ° C kunye ne-50% ngokulandelanayo.

3. Khangela amacandelo endlela ye-optical

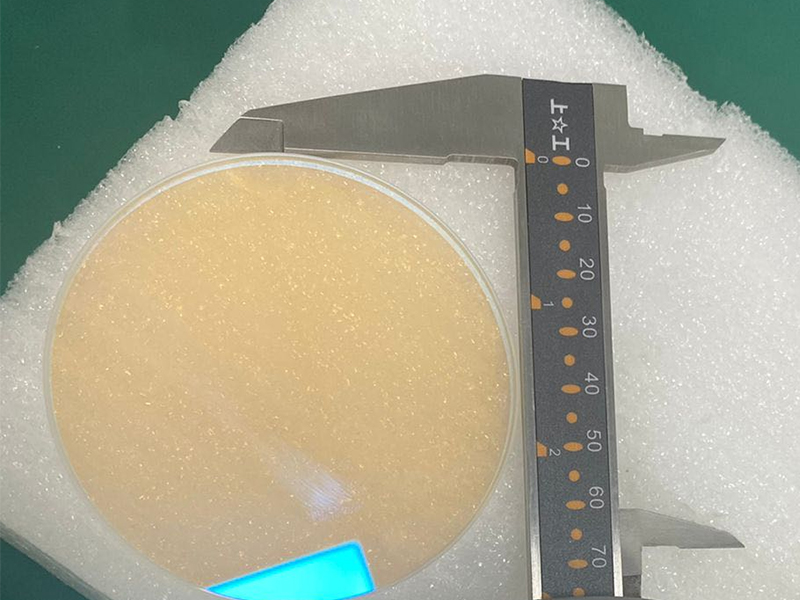

Ukuqinisekisa ukuba i-laser ibisoloko ikwimeko yokusebenza eqhelekileyo, emva kokusebenza ngokuqhubekayo okanye xa imisiwe kangangexesha elithile, amacandelo kwindlela ye-optical efana nentonga ye-YAG, idiaphragm ye-dielectric kunye neglasi ekhuselayo yelensi. kufuneka ihlolwe phambi kokuba kuqaliswe ukuqinisekisa ukuba izinto zamehlo azingcolisekanga., Ukuba kukho ukungcola, kufuneka kujongwe ngexesha lokuqinisekisa ukuba icandelo ngalinye le-optical aliyi konakala phantsi kwe-laser irradiation enamandla.

4. Khangela kwaye ulungise i-laser resonator

abaqhubi be-laser welding machine banokusoloko besebenzisa iphepha lomfanekiso omnyama ukujonga indawo yokuphuma kwelaser.Nje ukuba indawo engalinganiyo okanye ukuhla kwamandla kufunyenwe, i-resonator ye-laser kufuneka ihlengahlengiswe kwangexesha ukuze kuqinisekiswe umgangatho we-beam yemveliso yelaser.Abaqhubi be-debugging kufuneka babe nengqiqo eqhelekileyo yokhuseleko lokhuseleko lwe-laser, kwaye kufuneka banxibe iiglasi ezikhethekileyo zokhuseleko lwelaser ngexesha lomsebenzi.Ukulungelelaniswa kwe-laser kufuneka kuqhutywe ngabasebenzi abaqeqeshwe ngokukodwa, ngaphandle koko amanye amacandelo kwindlela ye-optical iya konakaliswa ngenxa yokungahambi kakuhle okanye ukulungiswa kwe-polarization ye-laser.

5. Ukucoca umatshini we-laser welding

Ngaphambi nasemva komsebenzi ngamnye, qala ucoce okusingqongileyo ukuze wome umhlaba kwaye ucoceke.Emva koko wenze umsebenzi omhle wokucoca izixhobo zomatshini we-LAG welding we-laser, kubandakanywa indawo yangaphandle ye-chassis, inkqubo yokujonga, kunye nomsebenzi, omele ungabikho kwi-debris kwaye ucoceke.Iilensi ezikhuselayo kufuneka zigcinwe zicocekile.

Oomatshini bokuwelda beLaserzisetyenziswa ngokubanzi ekusetyenzweni amazinyo amazinyo, ubucwebe iwelding, lesilicon steel sheet welding, ukuwelda isivamvo, ukuwelda ikepusi yebhetri kunye ukuwelda ngundo.

Ixesha lokuposa: May-06-2023