Umzobo weLaser & Cutting for ubucwebe

Abantu abaninzi bakhetha ukwenza ubucwebe babo bomntu ngokukrolwa kwelaser.Oku kunika abaqulunqi kunye neevenkile ezikhethekileyo kwizacholo isizathu sokuba batyale imali kobu buchwepheshe bale mihla.Ngenxa yoko, i-laser engraving yenza ukungena okubalulekileyo kwishishini lezacholo, ngokukwazi ukukrola phantse naluphi na uhlobo lwentsimbi kunye nokhetho olunikezelayo.Amakhonkco omtshato kunye nokuzibandakanya, umzekelo, unokwenziwa ngokukodwa ngokudibanisa umyalezo, umhla okanye umfanekiso onentsingiselo kumthengi.

Ukukrolwa kweLaser kunye nokumakishwa kwelaser kungasetyenziselwa ukubhala imiyalezo yobuqu kunye nemihla ekhethekileyo kwizacholo ezenziwe phantse kuyo nayiphi na intsimbi.Ngelixa ubucwebe bemveli benziwe ngegolide, isilivere kunye neplatinam, abaqulunqi bezacholo zanamhlanje basebenzisa ezinye iintsimbi ezifana ne-tungsten, intsimbi kunye ne-titanium ukwenza iziqwenga ezifashisayo.Ngenkqubo yokumakisha yelaser eyenziwe yiBEC LASER, kuyenzeka ukongeza uyilo olulodwa kuyo nayiphi na into yobucwebe kumthengi wakho, okanye ukongeza inombolo yesiriyali okanye olunye uphawu lokuzazisa ukuze umnini aqinisekise into leyo ngeenjongo zokhuseleko.Unokongeza isibhambathiso ngaphakathi komsesane womtshato.

Umatshini wokukrola we-laser uyimfuneko kuye wonke umenzi kunye nomthengisi kwishishini lobucwebe.Ukukrola isinyithi, izacholo, kunye nezinye izinto beziyinto eqhelekileyo kwakudala.Kodwa kutsha nje okumangalisayo kobuchwephesha obuphezulu, oomatshini bokukrola be-laser baphuhlisiwe abanokusombulula zonke iingxaki zakho zokumakisha zesinyithi kunye nezingezizo ezentsimbi.

Kutheni iLaser Engraving?

Umkrolo weLaser yenye indlela yangoku yokudala uyilo.Nokuba kukwenza umzobo wegolide wesitayile sakudala, ukukrola amakhonkco, ukongeza umbhalo okhethekileyo kwiwotshi, ukuhombisa intsimbi yomqala okanye ukwenza isongo ngokusikrola, i-laser ikunika ithuba lokusebenza kwiimilo ezininzi kunye nezixhobo.Ukumakishwa okusebenzayo, iipateni, ukuthungwa, ukwenziwa komntu kunye nokukrolwa kweefoto kunokufezekiswa kusetyenziswa umatshini welaser.Sisixhobo sokuyila kushishino loyilo.

Ke yintoni ekhethekileyo malunga nomkrolo welaser, kwaye yintoni umahluko phakathi kwale ndlela kunye nomzobo wesintu?Kancinci, ngokwenene:

√ I-laser ibonelela ngetekhnoloji ecocekileyo, ehambelana nokusingqongileyo, eyikhemikhali kunye nentsalela simahla kwaye ayidibani nobucwebe.

√ Itekhnoloji yeLaser inika umenzi wezacholo ithuba lokwenza uyilo olugqwesileyo ngaphandle komngcipheko kwinto ngokwayo.

√ Imizobo yeLaser iphumela kwiinkcukacha ezichanekileyo, ezihlala ixesha elide kunomzobo wesintu.

√ Uyakwazi ukukrola umbhalo okanye imizobo kwimathiriyeli kubunzulu obukhethekileyo.

√ Umkrolo weLaser usebenza ngakumbi kwiintsimbi ezinzima, unobomi obude.

I-BEC Laser ibonelela ngoomatshini bokukrola ubucwebe bale mihla belaser abachanekileyo nabachanekileyo kunye nokomelela okuphezulu.Inika uphawu lwelaser olungadibaniyo, olumelana ne-abrasion, olusisigxina phantse kulo naluphi na uhlobo lwemathiriyeli equka igolide, iplatinam, isilivere, ubhedu, intsimbi engatyiwa, i-carbide, ubhedu, i-titanium, i-aluminiyam kunye neendidi ngeendidi zealloyi neeplastiki.

Isicatshulwa sokuchonga, amanani othotho, iilogo zequmrhu, i-2-D data matrix, ibar coding, imifanekiso yegraphic kunye nedijithali, okanye nayiphi na idatha yenkqubo yomntu ngamnye inokuveliswa ngokukrolwa kwelaser.

Iinkqubo eziphezulu zokukrola i-laser ziyakwazi ukusika iintsimbi ezicekethekileyo zokwenza i-monogram kunye nezacholo zegama kunye nezinye iindlela zokusika eziyinkimbinkimbi.

Ukusuka kwiivenkile zobucwebe bezitena kunye nodaka ukuya kwiivenkile ezikwi-Intanethi, abathengisi banikezela ngeeneckout ezinamagama ezithengiswayo.Ezi nezacholo igama zilula ukwenza usebenzisa iinkqubo zokumakishwa laser eziphambili kunye laser lokumakisha software.Iinketho ezikhoyo zibandakanya: iiinishiyali, iimonograms, amagama okuqala kunye neziteketiso kwisimbo okanye ifonti oyikhethileyo.

Laser Cutting Machine for ubucwebe

Abaqulunqi bezacholo kunye nabavelisi bahlala bekhangela izisombululo ezithembekileyo zokuvelisa ukusika okuchanekileyo kweentsimbi ezixabisekileyo.Ukusika i-fiber laser enamanqanaba aphezulu ombane, ukugcinwa okuphuculweyo kunye nokusebenza okungcono kubonakala njengokhetho oluphezulu lwezicelo zokusika ubucwebe, ngakumbi izicelo apho umgangatho obalaseleyo, ukunyamezela okuqinileyo kunye nokuveliswa okuphezulu kuyadingeka.

Iinkqubo zokusika i-Laser zinokusika iintlobo ezininzi zezinto ezinobunzima obuhlukeneyo kwaye zifaneleke ngokufanelekileyo ukudala iimilo ezinzima.Ukongeza, iilaser zefiber zandisa ukuchaneka, ukuguquguquka kokusika kunye ne-throughput kwaye zibonelela ngesisombululo esisebenzayo esinexabiso eliphezulu lokuchaneka ngelixa kwangaxeshanye zibonelela abaqulunqi bezacholo inkululeko yokwenza imilo enzima enganyanzelwanga ziindlela zokusika zemveli.

Ukusika i-Laser yindlela ekhethiweyo yokwenza amagama anqunyulwe kunye neentsimbi ze-monogram.Enye yezona zicelo zobucwebe ezisetyenziswa kakhulu kwi-laser, ukusika kusebenza ngokuyalela umqadi we-laser onamandla aphezulu kwiphepha letsimbi elikhethiweyo igama.Ilanda inkcazo yegama kwifonti ekhethiweyo ngaphakathi kwesoftware yoyilo, kwaye izinto eziveziweyo ziyanyibilika okanye zitshiswe.Iinkqubo zokusika i-laser zichanekile ukuya kwii-micrometer ezili-10, oku kuthetha ukuba igama lishiywe ngomgangatho ophezulu kunye nokugqitywa kwendawo epholileyo, ilungele i-jeweler yokongeza i-loops yokufaka ikhonkco.

Iipendenti ezisikiweyo zivela kwiintlobo ngeentlobo zesinyithi.Ingaba umthengi ukhetha igolide, isilivere, ubhedu, ubhedu, insimbi engenasici okanye i-tungsten, ukusika kwe-laser kuhlala kuyeyona ndlela ichanekileyo yokudala igama.Uluhlu lwezinto onokukhetha kuzo luthetha ukuba le yindlela engaphelelanga kwabasetyhini kuphela;amadoda ngokwesiqhelo akhetha iintsimbi ezinzima kunye nefonti engqindilili, kwaye amatye anqabileyo ngokubanzi azama ukubonelela zonke izinto ezikhethwayo.Intsimbi engatyiwayo, umzekelo, ithandwa ngamadoda kuba ivakalelwa kancinci ngayo, kwaye ukusika ngelaser kusebenza ngcono kwintsimbi kunayo nayiphi na enye indlela yokwenza.

Ukugqitywa kubaluleke kakhulu kumgangatho wokusikwa kwamagama, uyilo kunye neemonograms, kwaye esi sesinye isizathu sokuba ukusika i-laser lukhetho lokuqala lwamatye anqabileyo amaninzi.Ukungabikho kweekhemikhali ezinobunzima kuthetha ukuba isiseko sesinyithi singonakaliswa yinkqubo, kwaye umgca ocacileyo ushiya igama elinqunywe kunye nomgangatho ococekileyo olungele ukupholisa.Inkqubo yokupholisa ixhomekeke kwintsimbi ekhethiweyo kunye nokuba umthengi ufuna ukukhanya okuphezulu okanye ukugqitywa kwe-matte.

Apha ngezantsi kukho iingenelo ezimbalwa zoomatshini bokusika i-laser xa kuthelekiswa neendlela zokusika zemveli:

√ Ugqweso oluncinci kwiindawo ngenxa yezowuni encinci echaphazelekayo kubushushu

√ Ukusika iindawo ezintsonkothileyo

√ Ububanzi bekerfu emxinwa

√ Ukuphindaphinda okuphezulu kakhulu

Ngenkqubo yokusika i-laser unokwenza ngokulula iipateni zokusika ezintsonkothileyo kuyilo lwakho lobucwebe:

√ IiMonograms ezinxibelelanayo

√ Yenza isangqa kwiiMonograms

√ Igama Lezacholo

√ Uyilo oluntsonkothileyo lweSiko

√ Izidanga kunye namakhubalo

√ Iipateni ezintsonkothileyo

Ukuba ufuna umatshini wokusika ubucwebe obuphezulu be-laser, apha uncoma umatshini wokusika ubucwebe be-BEC be-laser.

Ubucwebe beLaser Welding

Kwiminyaka embalwa edlulileyo, ixabiso lezinto ezininzi ze-laser welding jewelry lehlile, nto leyo eyenza ukuba bafikeleleke ngakumbi kubenzi bezacholo, izitudiyo ezincinci zokuyila, iivenkile zokulungisa kunye neentsimbi zokuthengisa ngelixa zibonelela ngeempawu ezongezelelweyo kunye nokuguquguquka kumsebenzisi.Rhoqo, abo bathenge umatshini wokuwelda welaser wobucwebe bafumanisa ukuba ixesha, abasebenzi kunye nokugcinwa kwezinto eziphathekayo kufikeleleke kakhulu kunexabiso lokuqala lokuthenga.

Ubucwebe be-laser welding ingasetyenziselwa ukuzalisa i-porosity, i-platinum yokuphinda i-platinum okanye i-prong yegolide, ukulungiswa kwe-bezel, ukulungisa / ukulungisa amakhonkco kunye nezacholo ngaphandle kokususa amatye kunye nokulungisa iziphene zokuvelisa.Ukuwelda kweLaser kuphinda kuqwalaselwe ubume bemolekyuli nokuba zezinye ezifanayo okanye ezingafaniyo kwindawo yokuwelda, nto leyo evumela ukuba iialloyi ezimbini eziqhelekileyo zibe nye.

Ukuvelisa kunye nokuthengisa amatye anqabileyo okwangoku asebenzisa i-laser welders bahlala bemangaliswe kuluhlu olubanzi lwezicelo kunye nokukwazi ukuvelisa imveliso esemgangathweni ophezulu ngexesha elincinci kunye nezixhobo ezimbalwa ngelixa ususa ubushushu obugqithisileyo.

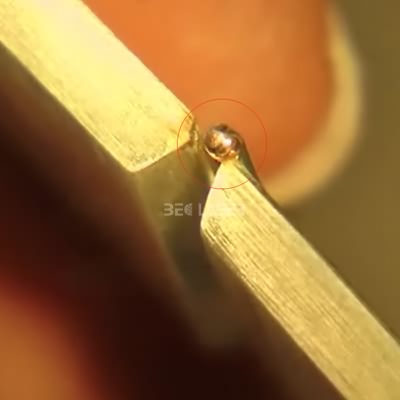

Enye yezinto eziphambili ekwenzeni i-laser welding esebenzayo kwimveliso yobucwebe kunye nokulungiswa yayikukuphuhliswa kwengcamango "yokuhamba ngokukhululekile".Ngale ndlela, i-laser yenza i-pulse yokukhanya kwe-infrared emileyo ejoliswe kwi-microscope's cross-hair.I-laser pulse inokulawulwa ngobukhulu kunye nobukhulu.Ngenxa yokuba ubushushu obuveliswayo buhlala buhlala kwindawo, abaqhubi banokuphatha okanye balungise izinto ngeminwe yabo, ukuwelda i-laser iindawo ezincinci ngokuchaneka kwe-pin-point ngaphandle kokwenza umonakalo kwiminwe okanye izandla zomqhubi.Le ngcamango ehamba ngokukhululekile yenza abasebenzisi basuse izixhobo zokulungiswa kweendleko kunye nokwandisa uluhlu lweendibano zobucwebe kunye nokulungiswa kwezicelo.

Iiweld zendawo ezikhawulezayo zigcina abasebenzi bebhentshi ukuphuthaza okuninzi.Iiwelder zeLasers zikwavumela abaqulunqi ukuba basebenze ngokulula ngeentsimbi ezinzima njengeplatinam kunye nesilivere, kunye nokunqanda ukufudumeza ngempazamo kunye nokuguqula amatye anqabileyo.Isiphumo sikhawuleza, sicocekile ngumsebenzi oqhuma phezulu.

Uninzi lwamatye anqabileyo anolindelo oluthile lwendlela i-laser welder enokuthi okanye ingancedi ngayo kwishishini labo lobucwebe.Emva kwexesha elifutshane ngelaser, iinkampani ezininzi zithi i-laser yenza okungaphezulu kunokuba bebecinga ukuba kuya kuba njalo.Ngomatshini ochanekileyo kunye noqeqesho olufanelekileyo, uninzi lwamatye anqabileyo luya kubona utshintsho oluphawulekayo kwixesha kunye nemali echithwe kule nkqubo entsha.

Apha ngezantsi kuluhlu olufutshane lwezibonelelo ze-laser welding:

√ Ukuphelisa imfuno yemathiriyeli ye-solder

√ Azisekho iinkxalabo malunga nekarati okanye ukuthelekisa umbala

√ I-Firescale kunye nokuvuthwa kuyapheliswa

√ Ukubonelela ngokuchaneka okucocekileyo, okucocekileyo okudityanisiweyo kwelaser

√ I-Laser weld spot ubukhulu busukela ku-0,05mm - 2,00mm

√ UkuYilwa kwePulse yePhulo eNgcono

√ Ubushushu bendawo buvumela "i-multi-pulsing" ngaphandle kokonakalisa umsebenzi wangaphambili

√ Incinci, iselula, inamandla kwaye kulula ukuyisebenzisa

√ Isixokelelwano sokupholisa samanzi esixineneyo, esizimeleyo

Ukusetyenziswa kobucwebe belaser welding:

√ Lungisa uninzi lweentlobo zobucwebe kunye nezakhelo zeglasi yamehlo ngemizuzu

√ Weld naliphi na isayizi ubucwebe bejula ukusuka kwicastings enkulu ukuya kwifiligree iingcingo ezincinci

√ Hlaziya amakhonkco kwaye ulungise izicwangciso zamatye

√ Dibana ngokupheleleyo nezacholo zentenetya yedayimani

√ Izithuba zokuwelda ngelaser kwimiva yamacici

√ Lungisa iziqwenga zobucwebe ezonakeleyo ngaphandle kokususa amatye

√ Lungisa/Gcwalisa kwakhona imingxuma yeporosity kwiicastings

√ Lungisa/Hlanganisa kwakhona iifreyimu zeglasi yamehlo

√ Igqwesileyo kwizicelo ze-Titanium welding