IFayibha Laser Welding Machine-Handheld Uhlobo

Intshayelelo yeMveliso

Imowudi yokusebenza ye-fiber laser welding ebanjwe ngesandla, i-welding ebanjwe ngesandla iyaguquguquka kwaye ilungele, kwaye umgama we-welding ubude.Ukusebenzisa i-handheld welding gun ukutshintshela indlela yokukhanya emiselweyo yangaphambili ineenzuzo zokusebenza okulula, i-welding seams emihle, isantya esikhawulezayo sokudibanisa kwaye akukho zixhobo.

Kuba ukuwelda iipleyiti ezibhityileyo steel stainless, iipleyiti zentsimbi, iipleyiti galvanized kunye nezinye izinto zetsimbi, inokuthi ngokugqibeleleyo endaweni yemveli argon arc welding, welding yombane kunye nezinye iinkqubo.Umatshini wokuwelda we-laser obambe ngesandla usetyenziselwa ukuwelda i-laser yomgama omde kunye nezixhobo zokusebenza ezinkulu.Indawo echaphazelekayo ukushisa incinci ngexesha le-welding, kwaye ayiyi kubangela ukuguqulwa komsebenzi, i-blackening, kunye nemikhondo emqolo.Ubunzulu be-welding bukhulu, i-welding iqinile, kwaye ukunyibilika kwanele.Akukho mbobo kwinxalenye yeconvex yezinto ezityhidiweyo kwi-melting pool kunye ne-substrate.

I-Handheld Fiber laser welding machine sisixhobo sokuwelda i-laser esidibanisa imiqadi yelaser yamandla aphezulu kwifiber optical, emva kokusasazwa komgama omde, emva koko iguqulwe ibe zizibane ezihambelanayo ngesipili sokudityaniswa ukuze sigxile kumsebenzi wokuphumeza ukuwelda.Iindlela ze-welding ziquka i-welding ethe nkqo, i-welding paraller, i-stitch welding njalo njalo.

Iimbonakalo

1. Isantya se-welding ekhawulezayo, amaxesha angama-2 ~ 10 ngokukhawuleza kune-welding yendabuko.

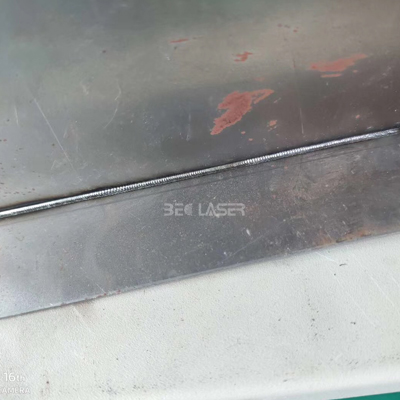

2. I-weld seam incinci, ubunzulu bokungena bukhulu, i-taper incinci, ukuchaneka kuphezulu, ukubonakala kugudileyo, kucaba kwaye kuhle.

3. Ubungakanani be-thermal deformation buncinci, kwaye indawo yokuncibilika kunye nommandla ochaphazelekayo wokushisa uncinci kwaye unzulu.

4. Izinga lokupholisa eliphezulu, elinokuthi lidibanise isakhiwo esihle se-weld kunye nokusebenza kakuhle ngokubambisana.

5. I-laser welding ine-consumables encinci kunye nobomi benkonzo ende.

6. Ukusebenza ngokulula akukho mfuneko yoqeqesho, ilungele ngakumbi indalo.

Isicelo

I-laser welding ingasetyenziselwa ukuwelda insimbi engenasici, i-aluminiyam, ubhedu, ichromium, i-nickel, i-titanium kunye nezinye isinyithi okanye i-alloys, ingasetyenziselwa iintlobo ezahlukeneyo zokuwelda phakathi kwezinto ezahlukeneyo, ezinje: ubhedu - ubhedu, i-titanium - igolide, i-Titanium - molybdenum, nickel - ubhedu njalo njalo.

Iiparamitha

| Umzekelo | HW1000 | HW1500 | HW2000 |

| Amandla eLaser | 1000W | 1500W | 2000W |

| Laser Wavelength | 1080±5 nm | ||

| Umthombo weLaser | Raycus ( MAX/JPT umthombo welaser ngokuzithandela) | ||

| Imo yokusebenza | Ngokuqhubekayo | ||

| Imo yokuPhuma | I-QBH esemgangathweni | ||

| Inkqubo yeWelding | Intloko ye-welding ye-QILIN ephathwa ngesandla | ||

| Umxhasi wocingo | Auto wire feeder | ||

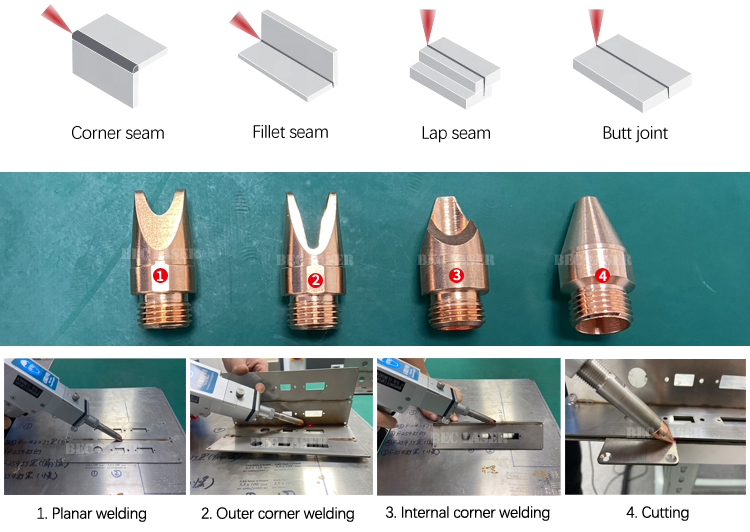

| Welding Nozzle | I-Planar, ikona yangaphandle, ikona yangaphakathi, i-nozzle yokusika | ||

| Ukumodareyitha rhoqo | 50~50,000Hz | 50~20,000Hz | 1-5,000Hz |

| Umgangatho weBeam | M2: 1.3 (25μm) | M2: 5-6 (50μm) | M2: 5-7 (50μm) |

| Red Guide Laser Power | 0.1~1 mW | 0.1~1 mW | 0.5~1 mW |

| Ukukhuselwa kweGesi | Nitrogen okanye Argon | ||

| Inkqubo yokupholisa | Inkqubo yokupholisa amanzi | ||

| Ubushushu bokusebenza | 0 °C - 35 °C ( Akukho ukujiya) | ||

| Amandla Aphelele | ≤6KW | ≤7KW | ≤9KW |

| Imfuneko yamandla | 220V±10% 50Hz okanye 60Hz | 220V±10% 50Hz okanye 60Hz | 380V±10% 50Hz okanye 60Hz |

| Ubungakanani bokuPakisha kunye nobunzima | Machine: Eround 127 * 73 * 129cm, 198KG; ucingo Feeder: Eround 69 * 59 * 64cm, 48KG. | ||

Iisampulu

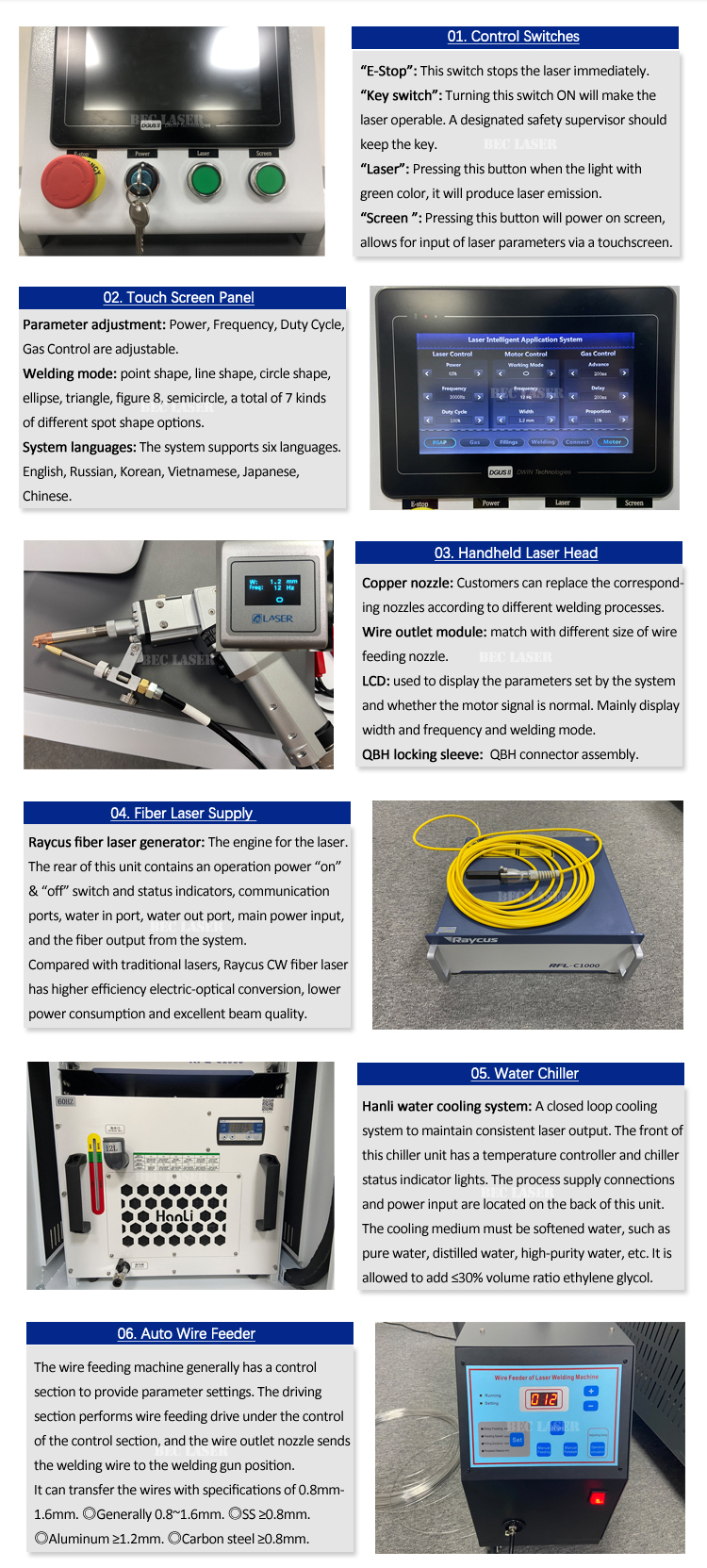

Ulwakhiwo

Iinkcukacha