ICantilever Laser Welding Machine-Ngengalo Eyonqenayo

Intshayelelo yeMveliso

Umatshini we-laser welding welding ikwalisebe lomatshini we-laser welding.Umgaqo osebenzayo kukusebenzisa i-high-energy laser pulses ukufudumeza kwendawo izinto kwindawo encinci.Amandla emitha yelaser asasazwa kwizinto ngokuqhuba ubushushu, kwaye izinto ziyanyibilika ukwenza ichibi elithile elityhidiweyo.

Luhlobo olutsha lwendlela ye-welding, ngokukodwa ukuwelda kwezinto ezinodonga oluncinci kunye namalungu achanekileyo.Inokuqonda i-welding, i-butt welding, i-stitch welding, i-welding yokutywina, njl.I-deformation encinci, isantya se-welding ekhawulezayo, i-welding seam egudileyo kunye nenhle, akukho mfuneko okanye ukusetyenzwa okulula emva kwe-welding, umgangatho ophezulu we-welding, akukho mingxunya yomoya, ulawulo oluchanekileyo, indawo encinci yokugxila, ukuchaneka kokuma okuphezulu, kunye nokulula ukuyiqonda i-automation.Oomatshini bokuwelda belaser bamandla aphezulu baye baziswa, abanokuqonda iintlobo ezahlukeneyo zoomatshini bokuwelda belaser kunye nokulungiswa kwezinto ezityebileyo.

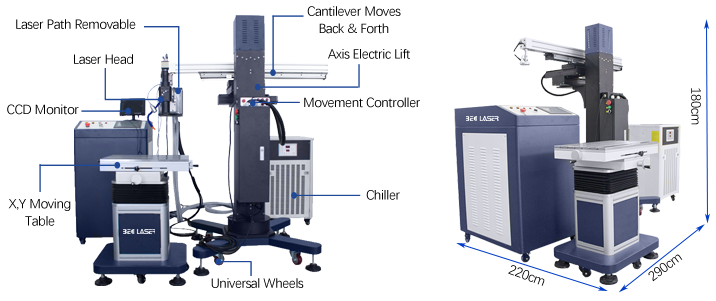

Ingalo ye-cantilever inokuguqulwa kuzo zonke iindlela kunye nee-angles.Nokuba isikhunta asinakushukuma, ingalo ye-cantilever inokuhamba ngokukhululekileyo, isombulule kakhulu i-welding enzima, iphucule ukusebenza kakuhle.Umtshini unokutshiza indawo emxinwa, i-welding enzulu yokulungiswa kombhobho, ayiyi kulimaza udonga olujikelezileyo.Ayizukuyikhubaza imveliso yokungunda okanye itshone ijikeleze i-weld pool.

Iimbonakalo

1. Umthombo we-laser usebenzisa iteknoloji yaseJamani ephucukileyo, imodyuli ehonjiswe ngegolide.Inophawu lwamandla aphezulu, ukusebenza okuzinzileyo kunye nokugcinwa lula.

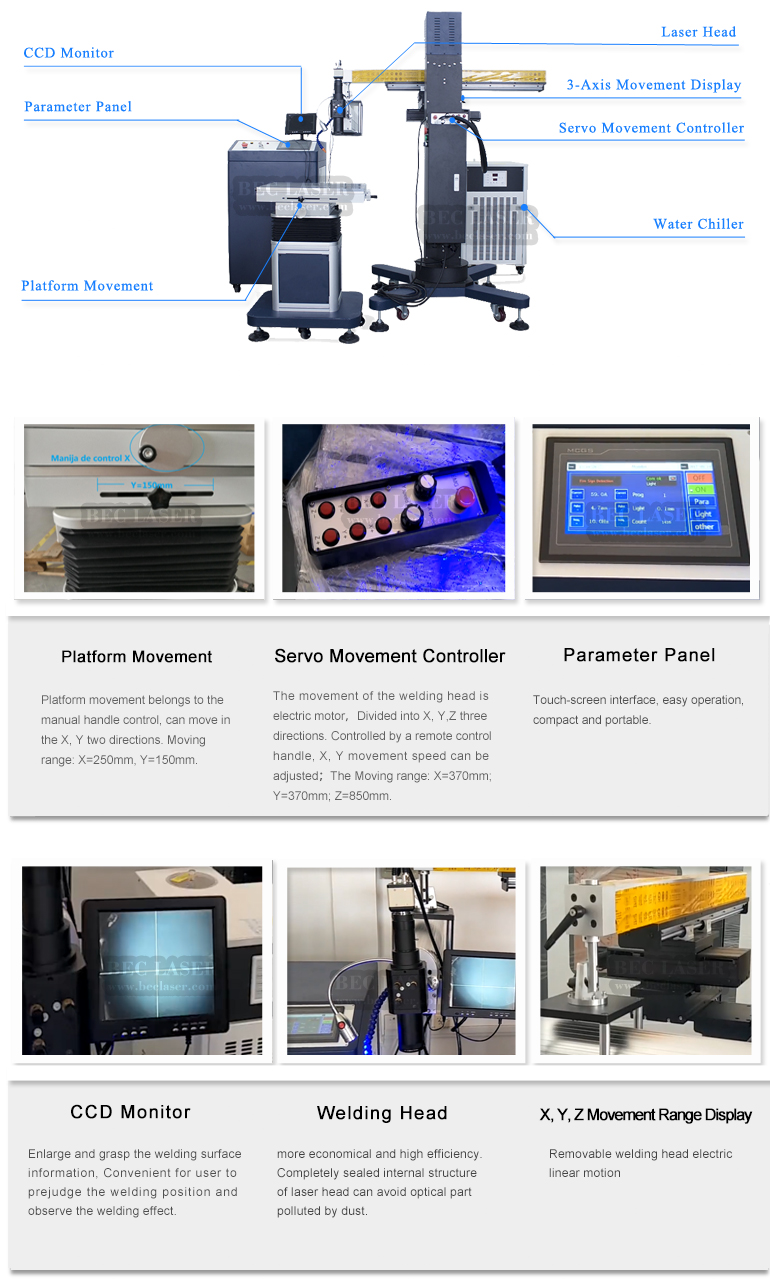

2. Iphaneli yesikrini sokuchukumisa ukulungelelanisa iiparamitha, ezilula kwaye zilungele.

3. Ibhentshi yomsebenzi i-X, i-Y intshukumo usebenzisa isikrufu esichanekileyo sebhola kunye ne-high-precision ethe ngqo yesikhokelo sokukhanya kwesitimela kunye ne-flexible, indawo echanekileyo, ithwala ukuya kuma-200 kg;

4. Intloko ye-laser inokutyibilika ngasemva naphambili, ukuphakamisa i-manual, intloko ye-laser inokujikelezwa ngokulula i-180 degrees, kulula ukulungisa i-welding nayiphi na icala;

5. Ixhotyiswe ngokulawula okude, ukulungiswa okuguquguqukayo kwe-360 degrees angle position of welding.Ngokujonga ukungunda okukhulu, akufuneki ibhentshi yokusebenzela, ngokuthe ngqo emhlabeni okanye i-forklift mold welding.

Isicelo

Yayisetyenziselwa ukulungisa imingundo emikhulu/ukubunjwa kwakhona.Izinto ezinokuthi zidityaniswe zibanzi: intsimbi yokusebenza ebandayo, intsimbi yokusebenza eshushu, intsimbi yensimbi yenickel, ingxubevange yentsimbi, ingxubevange ye-aluminiyam ephezulu, njl njl. Ezinye iintsimbi ezifana nobhedu, i-aluminium-magnesium alloy, titanium, kunye neplatinam nazo ziyasebenza.

Iiparamitha

| Umzekelo | BEC-MW200C | BEC-MW300C | BEC-MW400C | BEC-MW500C |

| Amandla eLaser | 200W | 300W | 400W | 500W |

| Laser Wavelength | 1064 nm | |||

| Max.I-Single Pulse Energy | 80J | 100J | 120J | 150J |

| Uhlobo lweLaser | ND:YAG | |||

| Laser Pulse Frequency | 0.1-100Hz | |||

| Pulse Ububanzi | 0.1-20ms | |||

| Indawo yokusebenza | Iqonga elihambayo uluhlu: X=250mm, Y=150mm, ithwala ukuya kuthi ga kwi-200KG | |||

| Cantilever Movement | X=370mm, Y=370mm, Z=850mm | |||

| Iinkqubo zokuPhonononga | Imakroskopu okanye i-CCD monitor ungayikhetha | |||

| Inkqubo yokulawula | Ulawulo lwenkqubo yeMicrocomputer | |||

| Ukutya umbane | 6KW | 10KW | 12KW | 16KW |

| Inkqubo yokupholisa | Ukupholisa amanzi | |||

| Imfuneko yamandla | 220V±10%/380V±10% 50Hz okanye 60Hz | |||

| Ubungakanani bokuPakisha kunye nobunzima | Umatshini: 295x105x195cm, i-chiller yamanzi: 60x58x108cm;Ubunzima obupheleleyo malunga ne-510KG | |||

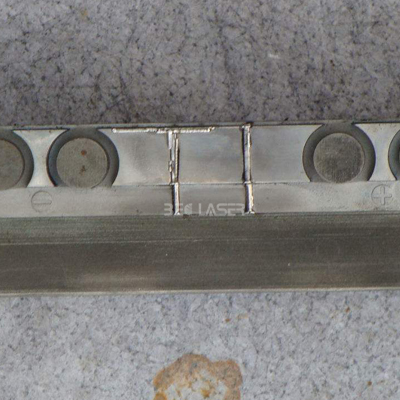

Iisampulu

Ulwakhiwo

Iinkcukacha